Understanding Mining’s Challenges

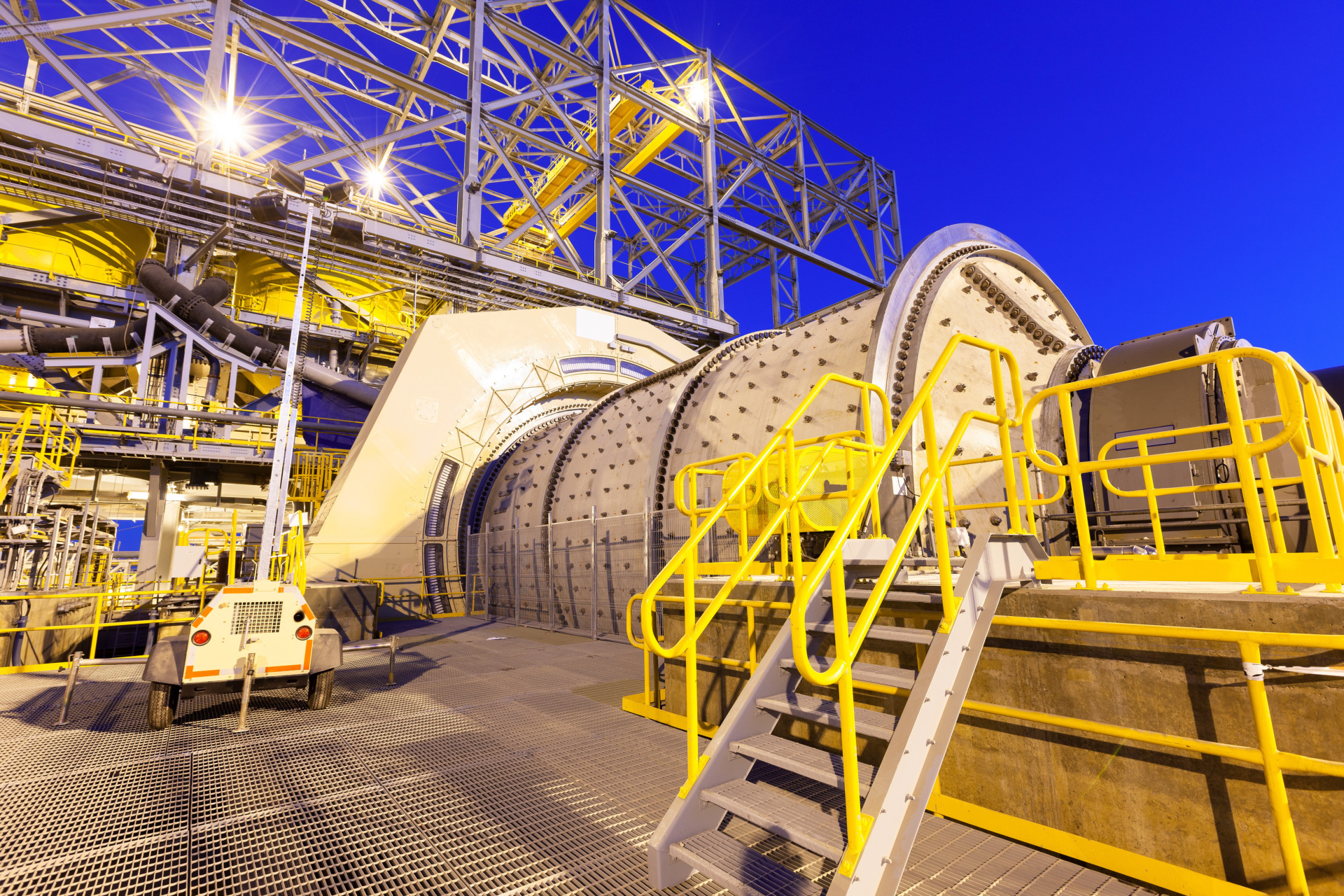

We know the unique complexities of mining and extraction site.

From remote locations to high energy demands, our predictive maintenance and performance solutions address the unique challenges of the mining industry, ensuring reliability and efficiency in the harshest conditions.

Sensitive natural areas

Remote locations

Corrosive environments

Extreme temperatures

High energy consumption

Worker safety

Ensuring the Performance of Mining and Extraction Assets

From crushers to conveyor systems, we help prevent equipment failures that could bring extraction and processing operations to a halt.

Our expertise covers a broad spectrum of mining-specific equipment, including:

- Ball mills

- Conveyor belts

- Cone crushers

- Flotation cells

- Jaw crushers

- Hydraulic shovels

- Slurry pumps

- Vibrating screens

- Fans

- Kilns

- Separators

- …

-

When I-care picked up on a critical issue with one of our engines, they saved us from a full-blown breakdown that would’ve taken weeks to sort, waiting on a replacement from the supplier. Thanks to their quick action, we kept things running and dodged a costly, drawn-out downtime.

Maintenance Manager — Mining Operations | Australia

The Benefits for Mining Operations

Maximized Asset Uptime

Maintain uninterrupted operations even in the most remote and hard-to-reach locations.

Optimized Maintenance

Streamline maintenance schedules and eliminate the need for costly emergency repairs.

Maximum Safety

Identify potential hazards early and reduce the risk of accidents involving machinery.

Extended Asset Lifespan

Enhance machinery durability to endure harsh climates and demanding production conditions.

Environmental Protection

Prevent ecological impact by ensuring safe and sustainable operations near sensitive habitats.

Reduced Energy Consumption

Optimize energy use across operations, lowering costs and supporting sustainability.

Our Comprehensive Approach

Predictive Maintenance

Robust

Sensors

Advanced

Analytics Software

Expert

Services

Our robust sensors monitor critical equipment reliability, such as ball mills and conveyor belts, in harsh environments. Our software platform analyzes the data collected to detect anomalies and assess asset health. Additionally, our experts provide services like infrared thermography and oil analysis for in-depth diagnostics.

Industrial Performance

Reliability

Engineering

Reliability-Centered

Lubrication

Our experts define and implement best practices to ensure efficient mining operations and continuous improvement. Through reliability-centered lubrication, we extend the life of heavy-duty machinery and reduce the likelihood of failures in harsh mining conditions.