Changing the Way

the World Performs

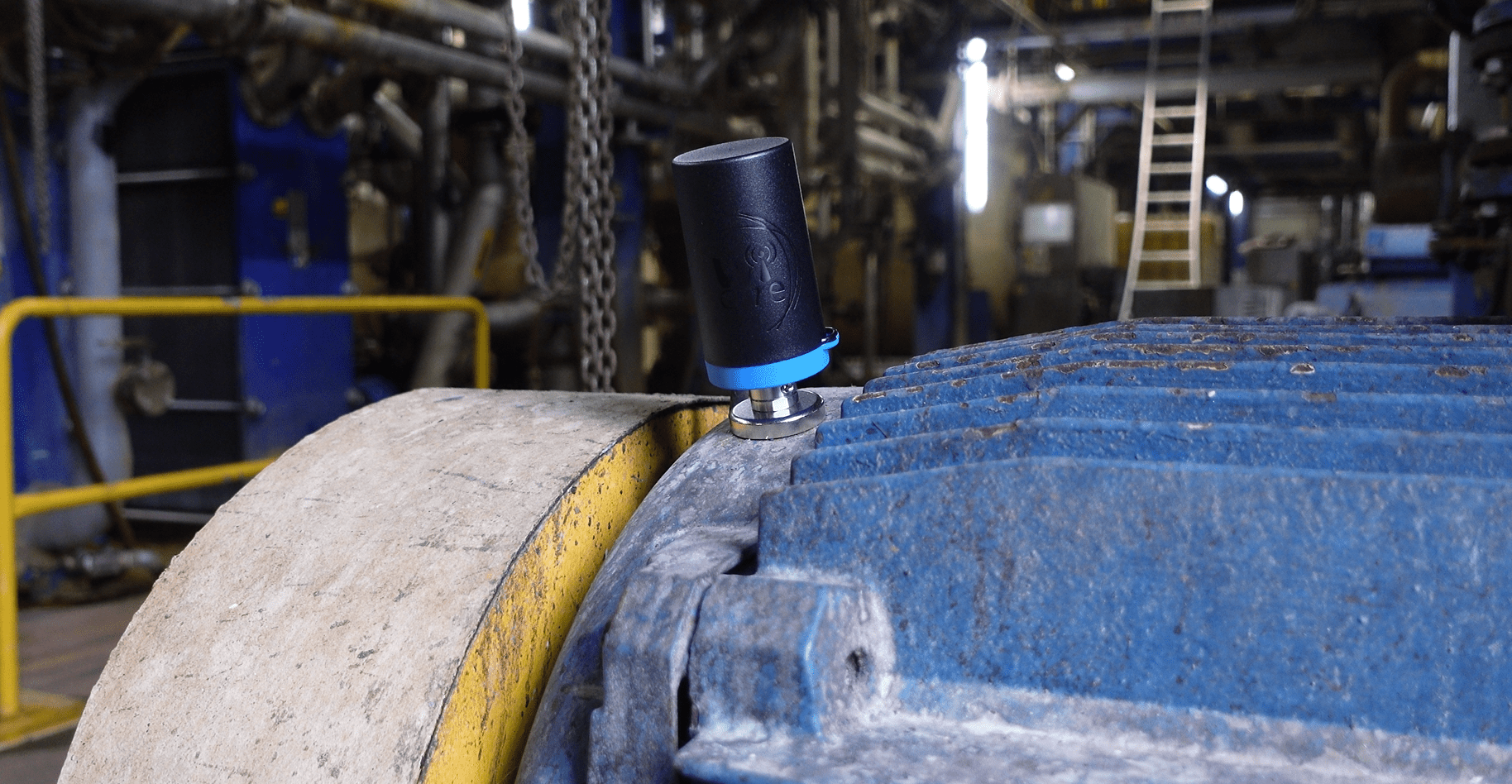

Achieve unprecedented asset reliability and performance with I-care patented monitoring IoT, AI-driven insights, and worldwide field expertise.

Achieve Next-Level Performance

Is Your Production Up to the Challenge?

Asset Uptime

Prevent machine downtime and unplanned maintenance based on risk profile and asset condition.

Cost Reduction

Decrease process variability and minimize maintenance and production costs.

Maximum Safety

Maintain machinery in optimal condition and reduce the risk of malfunctions, enhancing workplace safety.

Asset Lifecycle Extension

Maximize asset lifespan and ROI

by reducing wear and tear.

Environmental Impact

Contribute to minimizing waste and energy consumption, supporting greener production.

Production Quality

Reduce process variability and optimize product quality along the production cycle.

Predictive Maintenance

A Unique End-To-End Approach

Experience a comprehensive approach designed to maximize asset reliability,

enhance maintenance efficiency, and minimize unexpected failures.

Other Services

We Go Beyond Predictive Maintenance

-

Your installation team was nice when they spoke to us. Our Reliability Technician said he really appreciated working with those guys and learned a fair bit from them. They explained everything regarding the sensors very well and they took more time to get the details of the installation right from what I could tell. They get an A+ in my book.

Michael Carden — Perdue Farms -

With I-care’s wireless monitoring, we’ve gone from weekly checks to real-time insights — even spotting the link between flow and vibration that helps us fine-tune performance. This success gives us the confidence to expand predictive maintenance to other critical assets.

Matthew Zhang — Block Lead Mechanical | Neste Singapore -

In the past, we looked at vibration measurements just before a major repair period – every 30 months. Now, we can look at asset performance monthly.

Esther van der Voort — Reliability Manager, Anthony Veder -

Anthony Veder is a trusted partner for major oil and energy companies in the world and prioritizes a safe work environment for its people. Being able to proactively identify and address issues with the cargo plant is critical to fulfilling those commitments to our customers and crew members.

Esther van der Voort — Reliability Manager, Anthony Veder -

If I had to describe our collaboration, I’d say that with I-care we have ‘peace of mind’. When we assign them a task, we can trust that it will be executed properly.

Lorenzo Debels — Technical manager, Lutosa -

We needed a partner with a thorough approach that could give us clear direction, information and advice about how to solve our safety issues. I-care works directly with our business units to add value locally, and their advice improves our global operations as well.

Jeroen Helders — Group Insurance and Risk Manager, Royal Cosun -

I-care provided much more than support; they brought expertise, methodology, and agility. Their presence for five months was flawless—no complaints, only results.I-care provided much more than support; they brought expertise, methodology, and agility. Their presence for five months was flawless—no complaints, only results.

Pierre-Alain Saurin — Site Manager, Syngenta -

We already had a relationship of trust with I-care, which managed to provide us with 8 people in a single operation and in a very short period of time.

Pierre-Alain Saurin — Site Manager, Syngenta -

I contacted I-care when our strategic machines broke down. I sent them a sketch, and we started renting Wi-care sensors. We were then able to monitor the engine of a machine and maintain it in good condition until its programmed technical stop. We replaced the engine: the production was not impacted, and we didn’t have any breakdowns.

Philippe Beringuet — Reliability Manager, Barry Callebaut -

I-care treats our assets as their own. If I had to describe them in one word, it would be “Partnership.”

Kris Reynders — Maintenance Manager, Chiyoda -

With I-care’s expertise in vibration measurements and the deployment executed across our fleet, we receive precise recommendations that enable us to take optimal actions to mitigate the risk of failure. Additionally, their agile approach accelerates this deployment and implementation process.

Julien Raes — Department Manager, DEME Group -

We have found that the whole I-care package is substantiated with a realistic assessment of its possibilities. It really fits our requirements. It not only reduces these spontaneous failures and increases the availability of the assets but also enables us to optimize maintenance costs and procedures.

Mario Flory — Asset Monitoring Engineer and Project Leader -

It’s always daunting when a third party is going to inspect your installations but I-care did this very professionally and hands-on.

Marcel van den Heuvel — Chief Technical Officer, Plukon Food Group -

The I-care team brought along exceptional technical know-how and interpersonal skills.

Pierre-Alain Saurin — Site Manager, Syngenta -

We no longer wanted to suffer breakdowns and operate in firefighter mode, but on the contrary, be able to anticipate them. This is what we can do thanks to the I-care installations on our cocoa grinders.

Philippe Beringuet — Reliability Manager, Barry Callebaut

Empowering

Any Industry

+1000

Employees

around the globe

35 centuries

of combined

employee experience

+35 offices

located in +15 countries

Enhancing Industrial Asset Health Across the World

Modern production environments require healthy assets to maintain a competitive advantage.

For over two decades, top industrial organizations have relied on I-care’s advanced maintenance technologies, proven methods, and extensive expertise to enhance their machine health decisions and asset management performance.

Articles

I-care in the News

Global Presence. Local expertise.

Wherever you are, our experts deliver solutions that help reduce downtime, optimize asset performance, and drive measurable cost savings—all with a deep understanding of your local needs.

-

Distributor – Mexico – Mexico City