Machinery Overview

The rotary blower is a key component of aeration systems commonly used in wastewater treatment and recycling facilities. It uses high-speed impellers to move large volumes of air for pneumatic product transport. This high-speed operation makes the system susceptible to mechanical issues such as bearing lubrication problems.

In this case, the 3-lobe blower has a functional speed of 4500 rpm. Functional speed is constant, but for startup, a VFD is used to ramp up speed.

Motor: 2990 rpm

Blower: 4500 rpm in production, ramp up with VFD.

Drive: belt and pulley transmission

Flow rate: +/- 28m³/ min

Monitoring Devices and Software Set-up

I-care reliability engineers installed four Wi-care™ vibration sensors — two on the motor and two on the blower — to detect potential faults.

Once installed, the Wi-care™ sensors continuously transmit machinery health data to I-see™, I-care’s AI-powered analytics platform. The software analyzes vibration patterns to distinguish between normal behavior, early signs of degradation, and critical alarms.

The insights generated by I-see™ are compiled into clear diagnostic reports that provide a complete overview of the health status of both the motor and the blower.

I-care analysts then review these reports to detect faults, diagnose potential issues, and provide actionable recommendations as outlined in the steps below.

Detailed analysis

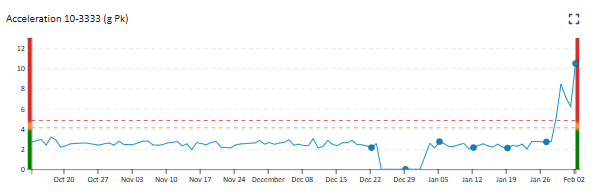

Step 1 | Detection of Issue

An increase in overall vibration energy was observed at the blower measurement points, prompting the I-care analyst to conduct a closer investigation.

Step 2 | Analysis

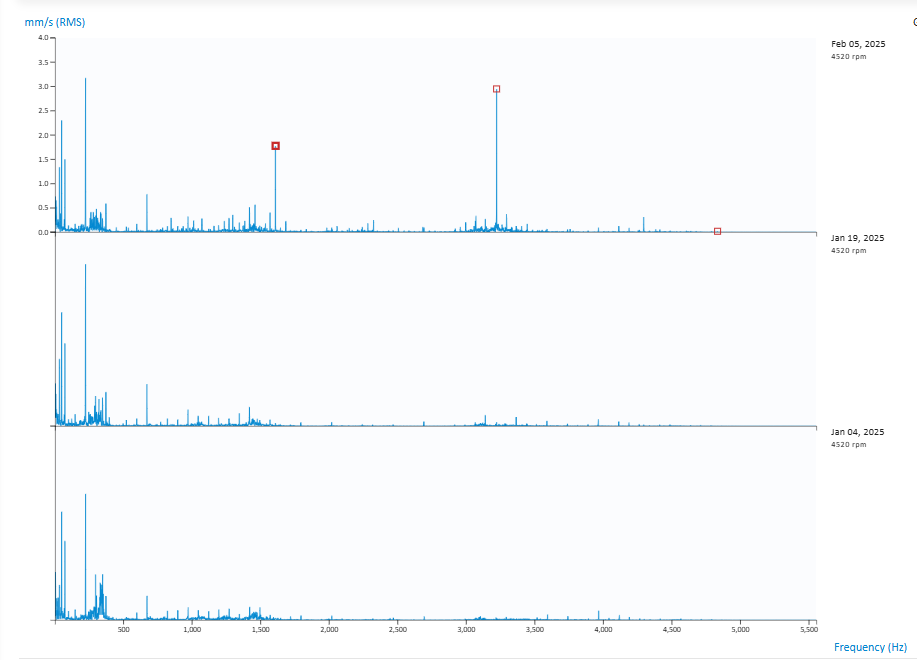

In the FFT spectrum, a frequency component was identified at 7.2× the blower’s running speed, which did not match any mechanical speed within the drive system.

The vibration energy concentration at a non-synchronous frequency, coupled with increasing amplitude, ruled out misalignment or imbalance as primary causes.

This spectral pattern indicated a localized defect, a bearing fault on the blower’s drive-side (DS) bearing.

Step 3 | Recommendation & intervention

To prevent unplanned downtime and the risk of production loss, the I-care expert advised scheduling an overhaul of the blower DS bearing at the earliest opportunity.

In the following days, vibration energy readings revealed a noticeable rise in amplitude at the identified defect frequency, confirming the fault’s progression.

Recognizing the accelerating deterioration, the I-care team issued a new report urging immediate intervention to avert a potential bearing failure.

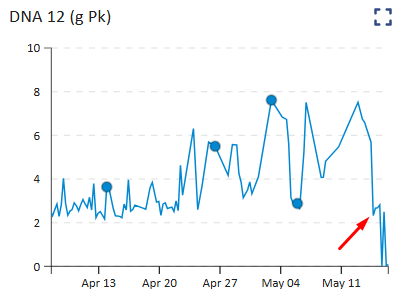

Acting swiftly on this recommendation, the maintenance team carried out a complete overhaul of the blower bearing.

Step 4 | Effectiveness

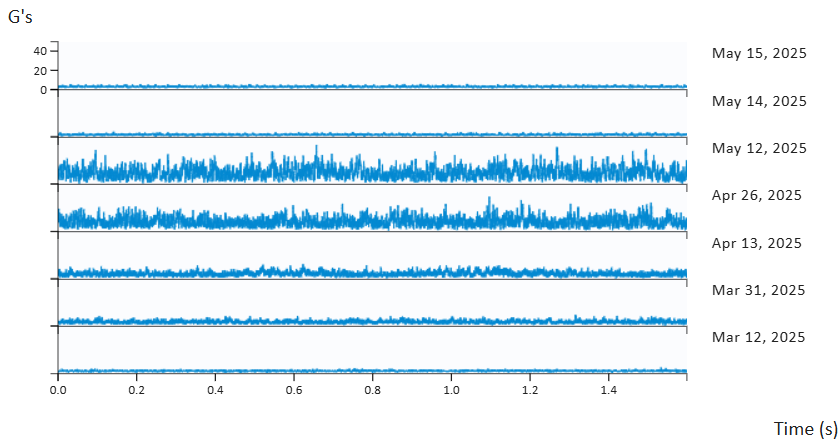

Post-intervention waveform readings showed a significant decrease in random impacting, confirming that the issue had been addressed.

Step 5 | Further Monitoring

Following the corrective action, I-care continued to monitor the blower system closely to ensure long-term stability. As of now, no recurrence of the abnormal vibration pattern has been observed.

Results

What Could Have Happened?

If the bearing defect had remained undetected, the blower could have overheated, posing an ignition risk in the flammable production area. Such an event could have led to a dust fire, resulting in severe production losses, equipment damage, and serious risks to personnel and nearby installations.

Thanks to early detection by I-care’s predictive maintenance system, a potentially catastrophic failure was turned into a planned maintenance action, ensuring safety and operational continuity.

Learn About Our

Success Stories

Our Solutions Span All Assets,

Including Yours.

Are you ready to enhance your efficiency?