Machinery Overview

This case focuses on a direct-drive 2.0 MW wind turbine generator that converts the blades’ rotational energy directly into electrical power.

Operating at low rotational speeds, the turbine relies on large main bearings to support the rotor shaft and ensure smooth, stable rotation.

Direct drive onshore wind turbine: 2 MW, 0-19 RPM

Monitoring Devices and Software Set-up

I-care reliability engineers installed Wi-care™ monitoring sensors to continuously track vibration levels. The sensors were strategically positioned on the main bearings and the generator structure, in accordance with VDI 3834 standards.

Once set up, Wi-care™ sensors transmitted machinery health data to I-see™, I-care’s AI-powered analytics platform. Its role is to categorize the data points and identify whether they indicate normal operation, early signs of degradation, or a critical alarm. The AI-generated insights are compiled into reports, providing a clear view of component health trends.

The I-care analysts then review these reports to identify potential issues and make recommendations, as outlined in the following steps.

Detailed analysis

Step 1 | Issue detection

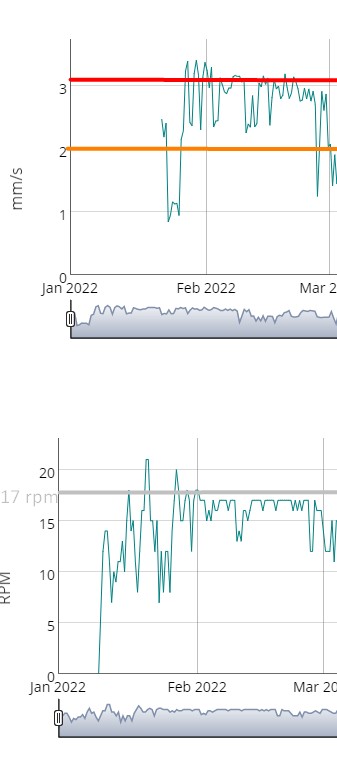

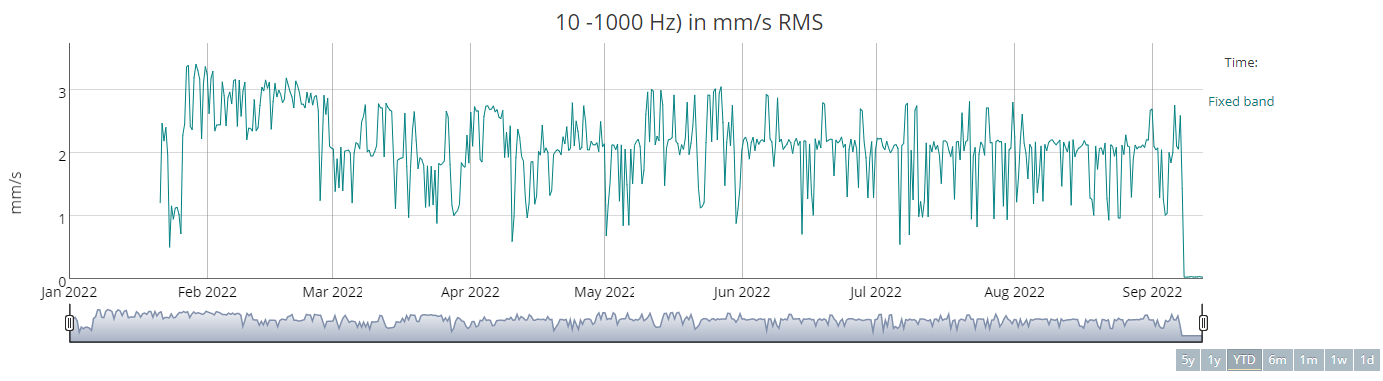

I-see™ detected vibration levels at the front main bearing exceeding alarm thresholds, with elevated activity in the 10–1000 Hz range.

The data showed vibration spikes synchronous with the rotor’s rotational speed, indicating that the anomaly was directly related to turbine operation.

Step 2 | Analysis

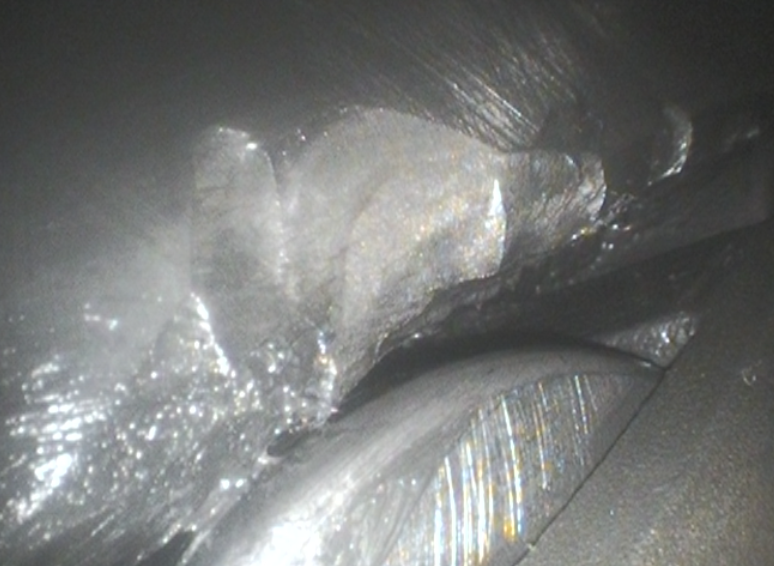

An I-care specialist analyzed the vibration data in accordance with VDI 3834 standards and identified a defect on the inner race of the front bearing.

The vibration peaks matched the expected BPFI frequency, confirming the fault.

Step 3 | Recommendation

The I-care engineer recommended purging the bearing lubrication system to remove debris and reduce wear. To assess the component’s internal condition, a borescope inspection was also advised.

The engineer also suggested curtailing power output to minimize stress on the bearing. By reducing the turbine speed from 19 RPM to 17 RPM, the load on the damaged bearing would decrease, allowing the machine to remain in operation with reduced risk until the inspection could be carried out.

Step 4 | Inspection

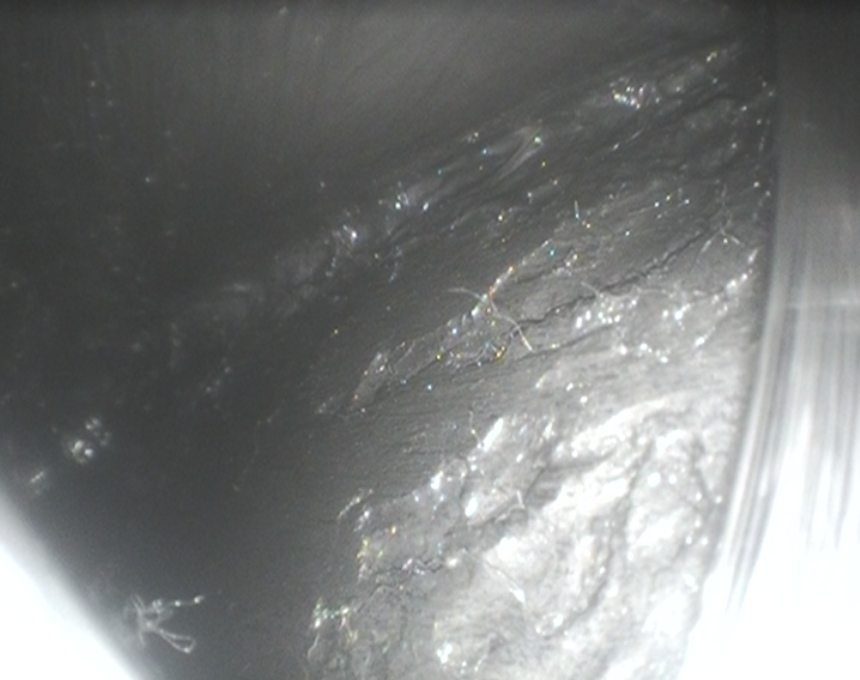

A maintenance operator performed the purging and did a borescope inspection through the available access ports. The inspection confirmed the vibration analysis diagnosis and revealed clear bearing damage.

A subsequent run test in freewheeling mode revealed oscillations consistent with drivetrain looseness, directly linked to the damaged bearing.

Step 5 | Monitoring

While awaiting the replacement of the front main bearing, I-care’s continuous monitoring confirmed that running at a lower speed kept vibrations within acceptable limits, allowing the turbine to operate with reduced risk and avoiding a costly shutdown.Together, these findings corroborated the analysis above and helped plan maintenance.

Step 6 | Effectiveness

Since replacing the front main bearing is a heavy operation requiring a crane to dismantle the turbine’s front section, the maintenance team decided to postpone the intervention until a suitable opportunity arises.

The turbine continued to operate safely under close monitoring for eight months before the replacement.

This strategy allowed the operators to group several turbines requiring crane-assisted maintenance, optimizing both costs and workforce efficiency.

Results

$180,000 Saved with I-care’s Early Breakdown Prevention

Without I-care’s predictive maintenance, the bearing defect would likely have gone undetected, leading to significant downtime and costly repairs. Instead, early detection, enabled by Wi-care™ sensors and I-see™ monitoring, and timely recommendations from I-care engineers ensured continuity and prevented operational disruption.

I-see™’s continuous monitoring and early alerts enabled the extension of turbine operation by eight months, adding about 2,000 MWh to its output and safeguarding roughly $180,000 in revenue, while preventing secondary damage to the generator or surrounding components.

Learn About Our

Success Stories

Our Solutions Span All Assets,

Including Yours.

Are you ready to enhance your efficiency?