In today’s industrial landscape, unplanned downtime and rising maintenance costs are significant threats to productivity and profitability. Fortunately, Predictive Maintenance (PdM) enables companies to boost their equipment uptime by over 30% and reduce asset failures by more than 70%.

Predictive Maintenance is a proactive data-driven maintenance strategy that relies on real-time condition monitoring techniques (such as vibration, ultrasound, oil analysis, etc.), advanced analytics, and Artificial Intelligence to deliver a comprehensive view of asset health, detect subtle degradation patterns, and forecast potential failures before they occur.

In this post, you’ll learn what PdM is through a detailed explanation of Predictive Maintenance and why it’s a game-changer for asset management and production uptime. We’ll also break down how Predictive Maintenance works, how it outperforms other maintenance methods, and what technologies and techniques it uses. Whether you’re starting from scratch or looking to scale, you’ll also discover how companies implement PdM step by step, and how modern solutions like Predictive Maintenance as a Service make it easier than ever to get started.

Table of Contents

Understanding Predictive Maintenance

Definition

Predictive Maintenance (PdM) is a proactive maintenance strategy that combines condition-monitoring techniques, such as ultrasound, vibration, and oil analysis, with advanced analytics and Artificial Intelligence to collect, analyze, and model asset health data. It detects subtle degradation patterns, simulates their evolution over time, and estimates remaining useful life (RUL).

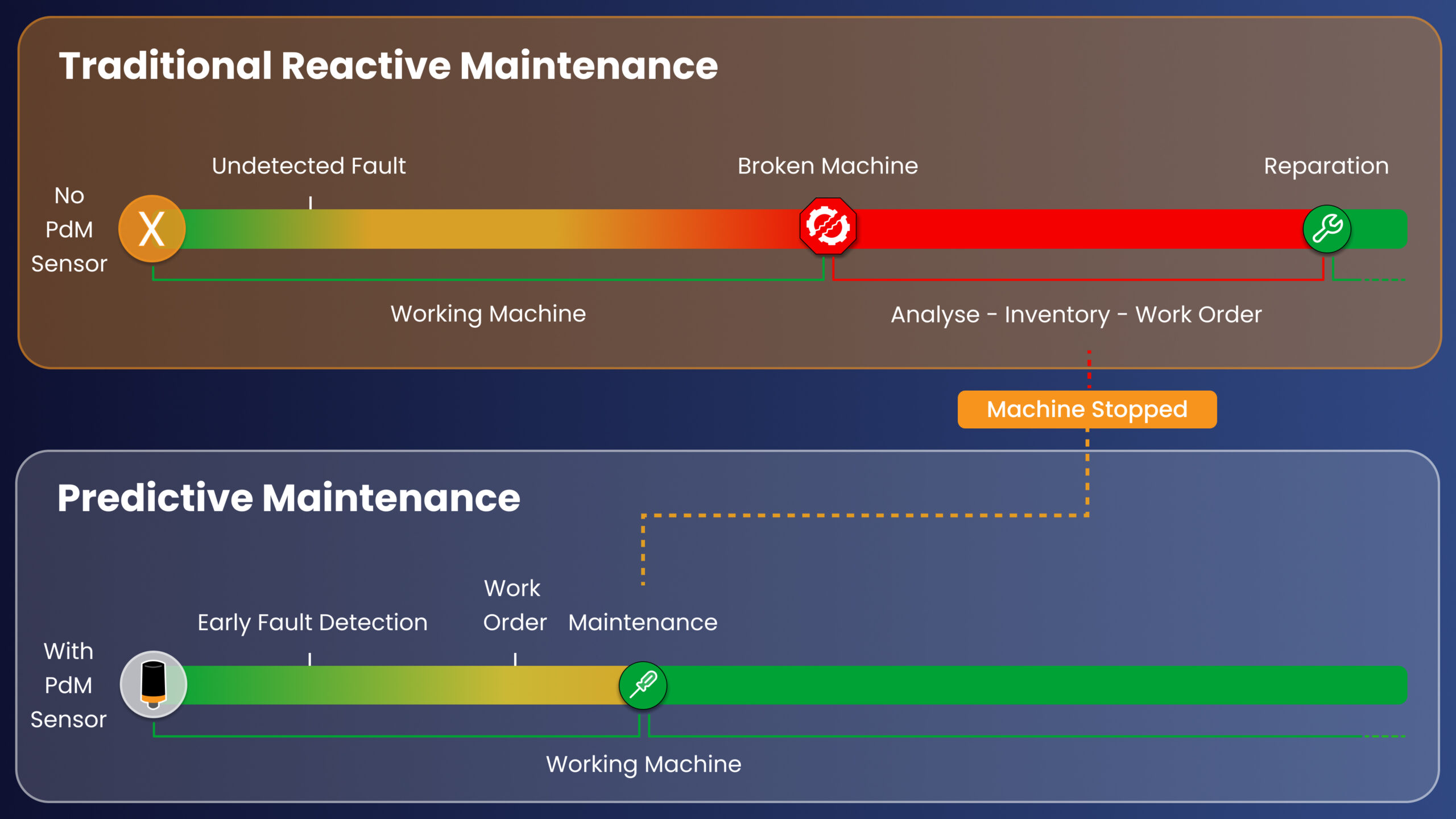

Where traditional reactive maintenance follows a “fail-and-fix” model, unplanned downtime leads to average direct costs of $55,100 per asset group and $308,300 per factory annually. Predictive Maintenance enables teams to anticipate potential failures and optimize maintenance operations and timing.

In the field, wireless vibration sensors and other IoT devices collect real-time asset health data. They transmit data to a machine learning-enhanced cloud platform that processes it to detect component wear patterns and predict RUL up to several months before failure. These insights enable maintenance teams to optimize operations and schedule interventions precisely when needed, thereby maximizing equipment availability, extending asset life, and minimizing premature replacements and delayed repairs.

How It Works

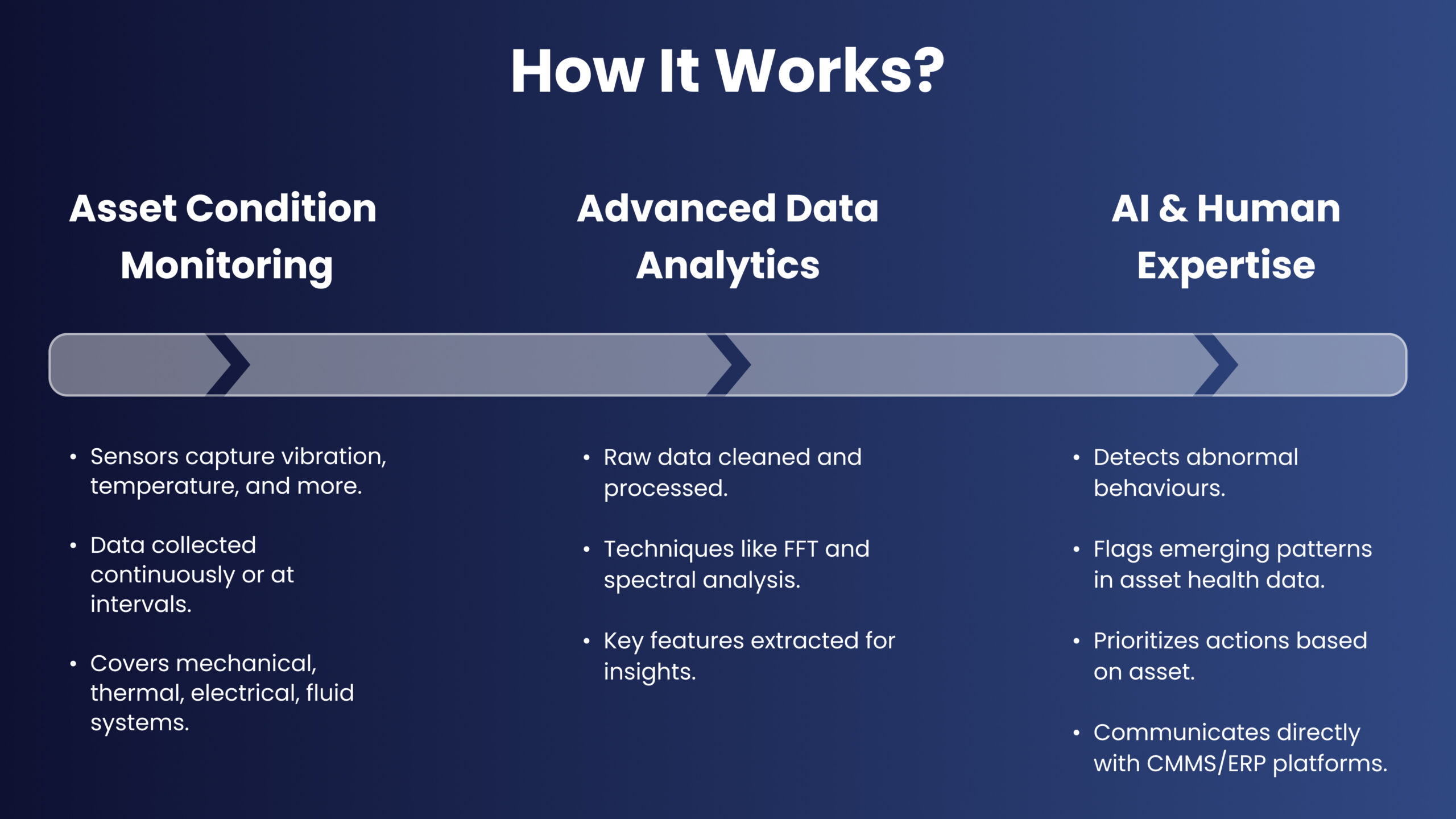

Predictive is built on several core elements:

- Asset condition monitoring

- Advanced data modeling & analytics

- AI-powered PdM platforms & Human expertise

Asset Condition Monitoring

Predictive Maintenance relies on specialized monitoring hardware that collects a wide range of time-stamped measurements.

For example, IoT monitoring sensors can capture vibration data across three axes and/or monitor temperatures ranging from -40°C to +125°C, providing detailed and reliable raw data on asset health.

During this data acquisition phase, measurement tools, including vibration and temperature sensors, infrared cameras, oil quality sensors, ultrasonic detectors, high-speed video systems, or motor circuit analyzers, feed a centralized analytics platform with machine health data collected continuously or at scheduled intervals. Those tools provide a baseline of operational conditions across mechanical, thermal, electrical, and fluid systems.

Advanced Data Modeling & Analytics

Predictive Maintenance utilizes advanced analytics platforms to convert raw condition measurements into actionable insights by applying the appropriate processing method. For example, vibration data is analyzed using Fast Fourier Transform (FFT), image processing allows the interpretation of thermographic and motion magnification data, and oil samples undergo spectral analysis.

During this data processing and feature extraction phase, different techniques filter out noise, highlight relevant features, and prepare data for interpretation.

AI-Powered PdM Platforms & Human Expertise

Predictive Maintenance platforms include an AI layer that first detects abnormal behaviours and flags emerging patterns in asset health data, then prioritizes actions based on asset criticality, failure risk, and operational impact, so maintenance teams can make timely and informed decisions and focus on the most urgent and high-value interventions. Interactive dashboards display asset health status and highlight actionable alerts, providing maintenance managers a live window into what needs attention and enabling efficient planning and resource allocation.

Then, experts review flagged patterns, validate or refine the system’s findings, and feed human insights into the platform. Through human-guided learning, combining expert feedback with historical data (real-time sensor inputs and scheduled measurements), Machine Learning models ingest more data and real-world outcomes, evolving into self-optimizing prediction models that continuously adapt. This allows PdM programs to maintain high diagnostic accuracy as operational environments evolve.

Finally, PdM platforms can communicate directly with Computerized Maintenance Management Systems (CMMS) or ERP platforms, automating work orders and aligning recommendations with existing workflows. In this way, AI-powered Predictive Maintenance platforms bridge the gap between diagnosis and operational execution, ensuring that the right action is taken, at the right time, on the right asset.

Predictive Maintenance vs. Other Proactive Types

Predictive Vs. Preventive Maintenance

Preventive Maintenance (PM) is based on predefined time or usage intervals, regardless of the asset’s actual condition. Time-Based Maintenance (TBM), scheduling interventions strictly by calendar or usage intervals, is essentially a subset of this approach.

For example, a maintenance team might change motor bearings every 5,000 hours, risking unnecessary replacements if they are executed too early or incurring unexpected downtime if they are delayed too long. In contrast, Predictive Maintenance (PdM) relies on real-time data to detect early signs of wear and predict potential failures, allowing teams to perform maintenance only when needed. By reducing needless interventions, lowering costs, and maximizing equipment availability, PdM delivers higher uptime and greater operational efficiency than PM.

Predictive Vs. Condition-Based Maintenance

Condition-Based Maintenance (CBM) relies on real-time monitoring of specific asset parameters, such as temperature, vibration, or pressure, and triggers maintenance as soon as readings cross predefined thresholds.

For example, a system may flag a motor for inspection if it overheats beyond 90°C, thereby preventing catastrophic failure but reacting only after damage has already begun to advance.

In contrast, Predictive Maintenance (PdM) identifies early signs of wear well before crossing any critical threshold. For instance, PdM can detect subtle winding insulation breakdowns in a motor at 75°C, well before CBM, which would trigger an alert at 90°C, giving teams days or weeks of lead time. This deeper foresight reduces unplanned downtime, avoids costly emergency repairs, and is especially critical in high-stakes environments (e.g., pharmaceutical cleanrooms) where a minor equipment issue can compromise product quality or regulatory compliance.

Predictive Vs. Prescriptive Maintenance

Prescriptive Maintenance (RxM) goes beyond prediction to prescribe or even automate the optimal maintenance response by balancing predicted asset health, parts availability, labor capacity, and production schedules.

For example, an RxM system might analyze bearing–wear predictions alongside inventory levels and shift rosters to recommend a combined service window for multiple machines, then automatically generate work orders in the CMMS to minimize downtime and labor costs.In contrast, Predictive Maintenance (PdM) focuses on detecting early signs of degradation and forecasting remaining useful life (RUL). While PdM alerts teams to “when” and “where” a failure is likely, it leaves “how” and “in what sequence” entirely up to planners. Prescriptive systems take PdM’s insights a step further, using optimization algorithms and business rules to prioritize tasks, allocate resources, and schedule interventions in the most efficient order.

Choosing the Right Type of Maintenance Strategy

Selecting the right proactive maintenance strategy depends on several factors, including the asset’s criticality (i.e., its importance to operations) and the consequences of its failure (e.g., production loss, safety hazards, or regulatory impact).

Other key considerations include the availability of monitoring technologies, the quality of existing data, internal technical resources, and the overall maturity of the maintenance program.

- Preventive Maintenance is best suited for non-critical or low-cost assets with predictable wear patterns, allowing teams to schedule maintenance effectively.

- Condition-Based Maintenance (CBM) is suitable for environments where monitoring is possible and failure patterns are not entirely predictable. It allows maintenance when equipment shows measurable signs of deterioration.

- Predictive Maintenance (PdM) is ideal for critical assets where failures are costly and downtime must be minimized, especially when real-time condition data is available to enable early detection and forecasting.

- Prescriptive Maintenance (RxM) targets complex and/or sensitive maintenance scenarios by balancing predicted health, parts, labor, and schedules to recommend and automate optimal responses.

| Type | Activation trigger | Cost Efficiency |

| Preventive (PM) | Scheduled intervals (e.g., time, usage cycles) regardless of equipment condition. | Low. It may lead to unnecessary maintenance and downtime. It consumes ~51% of all maintenance hours, even though many tasks add little reliability value. It locks significant capital in fixed assets. |

| Condition-Based (CBM) | Real-time equipment condition via sensors or inspections. | Mid. It requires an initial sensor investment. Maintenance is performed only when necessary, primarily based on manual inspections and predefined thresholds. |

| Predictive (PdM) | AI-driven forecasts using Machine Learning, historical, and real-time data from sensors. | High. It may require an upfront investment, unless you opt for an all-inclusive and scalable plan such as Predictive Maintenance as a Service solution. Well-executed PdM programs deliver 8 to 12% overall cost savings and cut facility downtime by 5 to 15%. |

| Prescriptive (RxM) | Algorithmic recommendations triggered by combined forecasts of asset health, parts availability, labor capacity, and production schedules. | Very high. It leverages PdM insights along with optimization logic to drive additional cost savings and minimize downtime, at the expense of higher integration effort. |

Once you’ve evaluated individual strategies (PM, CBM, PdM, RxM) against your asset’s needs, a higher‐level framework can guide which tactic goes where.

The following proven frameworks (RCM, RBM, and TBM) can help you match tactics to asset criticality, risk, and operational maturity:

- Reliability-Centered Maintenance (RCM) uses structured risk analysis (e.g., FMEA) to match each asset’s criticality and failure modes to the most effective maintenance approach, deploying PdM only where it adds value and avoiding needless sensor investments on low-impact equipment. As McKinsey research confirms, hybrid programs embedding PdM within an RCM framework deliver significantly higher ROI over standalone implementations.

- Risk-Based Maintenance (RBM) prioritizes assets by failure likelihood and consequence, often within an RCM program, to guide where techniques like PdM or CBM should be applied first.

- Time-Based Maintenance (TBM) schedules interventions at fixed calendar or usage intervals, independent of actual asset condition or risk profile, making it best suited as a baseline strategy for low-criticality assets rather than a standalone proactive framework.

With those frameworks in mind, start simple and scale toward full Predictive Maintenance. Phasing in a PdM program, beginning with your most critical or failure-prone assets, delivers the fastest gains in uptime, cost efficiency, and resource utilization. Although every asset operates in its own context, PdM remains the benchmark. Other maintenance approaches are used only where predictive coverage offers limited incremental value today.

Condition Monitoring Techniques in Predictive Maintenance

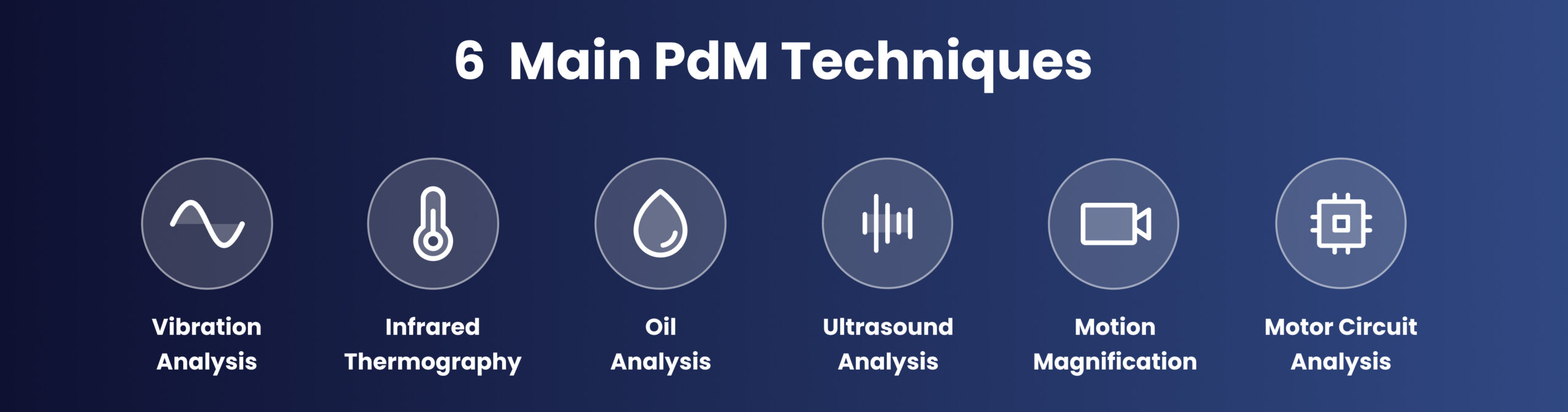

Predictive Maintenance relies on six core diagnostic methods to deliver 360-degree visibility into equipment health.

These methods enable maintenance teams to identify issues across a wide range of mechanical, electrical, and fluid systems, helping to anticipate and prevent up to 75% of potential failures.

- Vibration Analysis: Uses spectral frequency analysis to detect and identify early bearing faults, the primary failure mode it excels at, as well as issues as imbalances, misalignments, looseness in rotating equipment. It’s particularly effective on pumps, motors, gearboxes, and fans, where subtle mechanical shifts can quickly escalate into costly breakdowns.

- Infrared Thermography: Captures thermal images to identify overheating components, electrical faults, or insulation issues. It’s well-suited for monitoring electrical panels, bearings, motors, and switchgear, and can also support gas leak detection when equipped with spectrally tuned optics that capture the infrared signatures of specific gases.

- Oil Analysis: Analyzes lubricant properties to identify internal component wear, fluid contamination, and lubrication breakdown. It’s particularly valuable for engines, gearboxes, compressors, hydraulic systems, and turbines, where changes in oil condition provide early warning signs of mechanical distress.

- Ultrasound Analysis: Uses high-frequency sound waves to identify friction, turbulence, and acoustic anomalies in pressurized or mechanical systems, even in noisy environments where other methods struggle. It’s especially effective for valves, piping networks, compressed air systems, bearings, and electrical components, where early-stage leaks, faults, or discharge events produce ultrasonic signatures before becoming critical.

- Motion Magnification: Uses video-based analysis to amplify and visualize subtle vibrations and displacements in machinery or structures, making otherwise invisible motion patterns detectable. It’s particularly useful for piping systems, rotating equipment, support structures, and foundations, where early signs of instability, misalignment, or resonance can be identified before they escalate.

- Motor Circuit Analysis: Evaluates the electrical integrity of motor windings and circuits through voltage and current signature testing to detect insulation breakdowns, rotor bar defects, and phase imbalances. It’s especially valuable for motors, generators, transformers, and other electrically driven systems in manufacturing, energy, and HVAC environments, where early detection prevents failures and reduces energy losses.

Benefits of Predictive Maintenance

Unlike proactive maintenance strategies that rely on time-based schedules, PdM adapts dynamically to the actual health of the equipment.

Predictive Maintenance offers several advantages and delivers transformative value across 3 key dimensions:

Cost Savings

PdM reduces both direct and indirect maintenance costs.

PdM prevents unnecessary interventions and enables smarter, planned maintenance, minimizing spare parts consumption, reducing labor hours, streamlining logistics, and optimizing scheduling and resource allocation.

Beyond maintenance, PdM also helps prevent unexpected equipment failures, protecting production output, reducing quality issues, and avoiding costly waste, such as scrapped batches in regulated industries like pharmaceuticals.

On average, Predictive Maintenance lowers maintenance costs by about 25%.

Efficiency, Lifespan & Performance

PdM enhances operational continuity and extends asset life.

Predictive Maintenance uncovers early signs of degradation and prompts timely and targeted interventions, thereby increasing Overall Equipment Effectiveness (OEE), shortening changeover and/or start-up times, lowering energy consumption, and improving first-pass yield by ensuring machines operate within tight performance tolerances, reducing the risk of quality defects and rework.

Tackling wear before it accelerates extends mean time between failures (MTBF), keeps equipment within design tolerances, and safeguards long-term performance, so assets deliver consistent throughput and product quality throughout their service life.

On average, Predictive Maintenance extends asset lifespan by between 20 and 40%.

Safety & Environment

PdM helps protect workers and the environment.

PdM issues early alerts that avert fires, leaks, and mechanical breakdowns, giving teams the time to plan interventions more efficiently and keeping operations within safe limits, ensuring regulatory compliance, and lowering recordable incidents.

Tackling root causes before they escalate, such as detecting seal wear in industries like oil and gas, strengthens safety protocols, avoids waste linked to quality losses (scrap, rework, off-spec product), continually improves environmental performance, and supports Corporate Social Responsibility (CSR) and sustainability goals.

On average, Predictive Maintenance reduces by more than 10% risks in safety, health, environment, and quality.

Examples of PdM in Different Industries

With Predictive Maintenance, industries experience more than just a technical upgrade, they undergo a transformative shift in how they maximize uptime, optimize performance, and manage operational risk.

Here are four examples illustrating how PdM drives value; virtually any asset-intensive industry can reap similar benefits.

- Pharmaceutical Industry: PdM enables detection of subtle anomalies in various equipment categories, such as HVAC units, bioreactors, filtration systems, conveyors, bottling lines, and tablet presses, long before they threaten sterile conditions or product quality. This monitoring is performed continuously to prevent costly clean-room downgrades. PdM ensures batch quality, regulatory compliance, and uninterrupted production.

- Food and Beverage: PdM monitors conveyors, refrigeration units, and bottling lines, preventing mechanical failures that could lead to product spoilage, hygiene risks, or costly downtime. It minimizes unplanned failures that could disrupt production flow and reduce overall productivity. Predictive Maintenance helps maintain safety, efficiency, and compliance in high-speed processing environments.

- Chemical Processing: PdM spots early signs of seal wear, cavitation or starvation, vibration shifts, leakage, fouling, and overheating across key equipment, such as centrifugal and magnetic-drive pumps, liquid-ring and piston pumps, storage tanks, fans, rotary-screw, rotary-lobe, reciprocating compressors, gearboxes, and centrifuges. PdM also maintains steady throughput, protecting yield and productivity in continuous-flow environments.

- Wind Energy: PdM monitors gearboxes, main bearings, pitch- and yaw-drive systems, and generators long before faults escalate into costly failures or forced shutdowns. It triggers planned interventions rather than emergency call-outs, cutting crane-mobilization expenses and unplanned site visits. Predictive Maintenance gives maintenance teams time to state the right spare parts, avoiding shortages or overstock. It also increases turbine availability, extends drivetrain life, and boosts annual energy production.

Beyond these examples, Predictive Maintenance brings value to all industries, including automotive, building materials, energy, marine and offshore, mining and extraction, oil and gas, pulp and paper, and steel.

Implementing a Predictive Maintenance Program

Implementing Predictive Maintenance requires a structured approach built on key steps that blend strategy, technology, and continuous learning.

Here is a detailed explanation of the core steps to guide Predictive Maintenance implementation:

- Assess current maintenance practices and build the business case: Begin by auditing your maintenance operations (processes, schedules, tools, and KPIs) to uncover inefficiencies and pain points like unexpected downtime, over-servicing, or compliance gaps.

- Define scope and prioritize assets: Inventory all equipment and rank them by criticality (impact on safety, production, or compliance), historical “bad-actor” behavior, and maintenance-cost contribution. Leverage methods such as criticality assessments, bad-actor analysis, and cost benchmarking to focus on the highest-value candidates.

- Analyze failure modes and data requirements: For each prioritized asset, perform a Data Oriented Failure Analysis (e.g., I-care DOFA) or FMEA to map its likely failure modes and root causes. Identify the key condition indicators (e.g., vibration signatures, temperature trends, oil-particle counts) that consistently signal each specific type of failure. Then translate those indicators into concrete data requirements (sampling rates, sensor accuracy, and data retention) so you capture the right signals at the right frequency for effective predictive modeling.

- Select hardware based on a data-driven failure modes analysis: Choose sensors and data acquisition tools that align directly with your identified failure modes. Match each condition indicator (e.g., vibration frequency bands, temperature ranges, oil-particle concentrations) to an appropriate sensor type (e.g., Wi-care wireless vibration sensor) and mounting method. Specify requirements for:

- Sensor performance: measurement range, resolution, and accuracy

- Data acquisition: sampling rates, edge-processing capabilities, and connectivity (wired, wireless, gateway protocols)

- Environmental fit: ingress protection, temperature tolerance, and power constraints

- Deploy the hardware and collect data: Launch your PdM program on a small set of pilot assets or a single production line. Install your sensors and data acquisition tools according to the guidelines and site constraints. Commission each unit with configuration checks and functional tests to verify signal integrity, connectivity, and timestamp synchronization. Establish secure, reliable data pipelines, whether edge-to-cloud or on-premise, so that real-time condition data streams into your analytics platform. Finally, set up storage and data retention policies.

- Develop predictive analytics and forecasting models: Feed your collected condition data (historical and real-time) into analytics software (e.g., I-see platform) or managed services to build and train anomaly detection and prognostic models, supported by a detailed explanation of how each indicator correlates to failure modes. Leverage techniques such as statistical trend analysis or machine learning classifiers to detect early warning signs and forecast remaining useful life. Continuously validate model performance against known failure events, tune parameters, and retrain as new data flows in.

- Translate insights into dynamic maintenance workflows: Turn your model outputs into action by defining clear thresholds and workflows for each asset class. Integrate your PdM platform (e.g., I-see open platform) with your CMMS or ERP so that when a condition indicator exceeds its threshold, a work order is automatically generated. Specify response protocols (inspection steps, parts staging, and approval chains) tailored to each asset’s criticality and risk level.

- Pilot, monitor, and continuously improve: Track key performance indicators (MTBF, unplanned-downtime reduction, maintenance-cost savings) against your original targets. Use each prediction cycle’s outcomes to refine model parameters and optimize workflows. Gradually expand to additional assets as you validate ROI and mature your processes.

Want Expert Support to Implement Predictive Maintenance Effectively?

At I-care, with our comprehensive offering that includes hardware, software, and services, we help organizations implement PdM efficiently and effectively. Beyond deployment, we remain a long-term partner, continuously supporting your teams, bringing valuable insights and cutting-edge technologies, ensuring your Predictive Maintenance strategy evolves with innovation and industry best practices.

Data Management and Integration

Effective data collection and data management are the backbone of any successful Predictive Maintenance program. The accuracy of failure predictions depends entirely on the accessibility, quality, and consistency of your data, as well as the effectiveness of signal processing used to extract actionable insights from raw sensor inputs.

Sensors must be properly calibrated during manufacturing to accurately capture conditions such as temperature, vibration, and pressure. Reliable condition measurement is crucial to ensure that predictive models are fed with accurate and clean inputs.

Managing and integrating PdM data presents several challenges that companies must address to ensure reliability and scalability:

- Data volume: PdM systems often generate massive amounts of sensor data every second.

- Data variety: PdM uses both structured data (such as sensor readings and maintenance logs) and unstructured data (including inspection reports or technician notes) from diverse sources.

- Data quality: Predictive insights are only as reliable as the data on which they are based.

- Data latency: Predictions are only effective when delivered on time to enable action.

Adding to this complexity is the need for seamless data integration. A PdM program must consolidate and align inputs from and to multiple, fragmented sources, such as:

- IoT sensors mounted on critical assets and, where needed, edge devices installed nearby.

- Cloud infrastructure for real-time analytics and scalable data pipelines.

- Third-party data platforms, including external OEM-provided condition monitoring portals, and API-connected reliability databases.

- Legacy systems, including ERP, Computerized Maintenance Management System (CMMS), or Enterprise Asset Management platforms (EAM).

Ready to Build a Predictive Maintenance Ecosystem That Truly Scales?

At I-care, we help companies navigate this complexity. Our experts provide end-to-end support in data management, system integration, and industrial data management standardization. We help you build a PdM ecosystem that embodies a next-generation-ready concept, incorporating the latest maintenance technology and advancements to remain technically robust, scalable, and reliable.

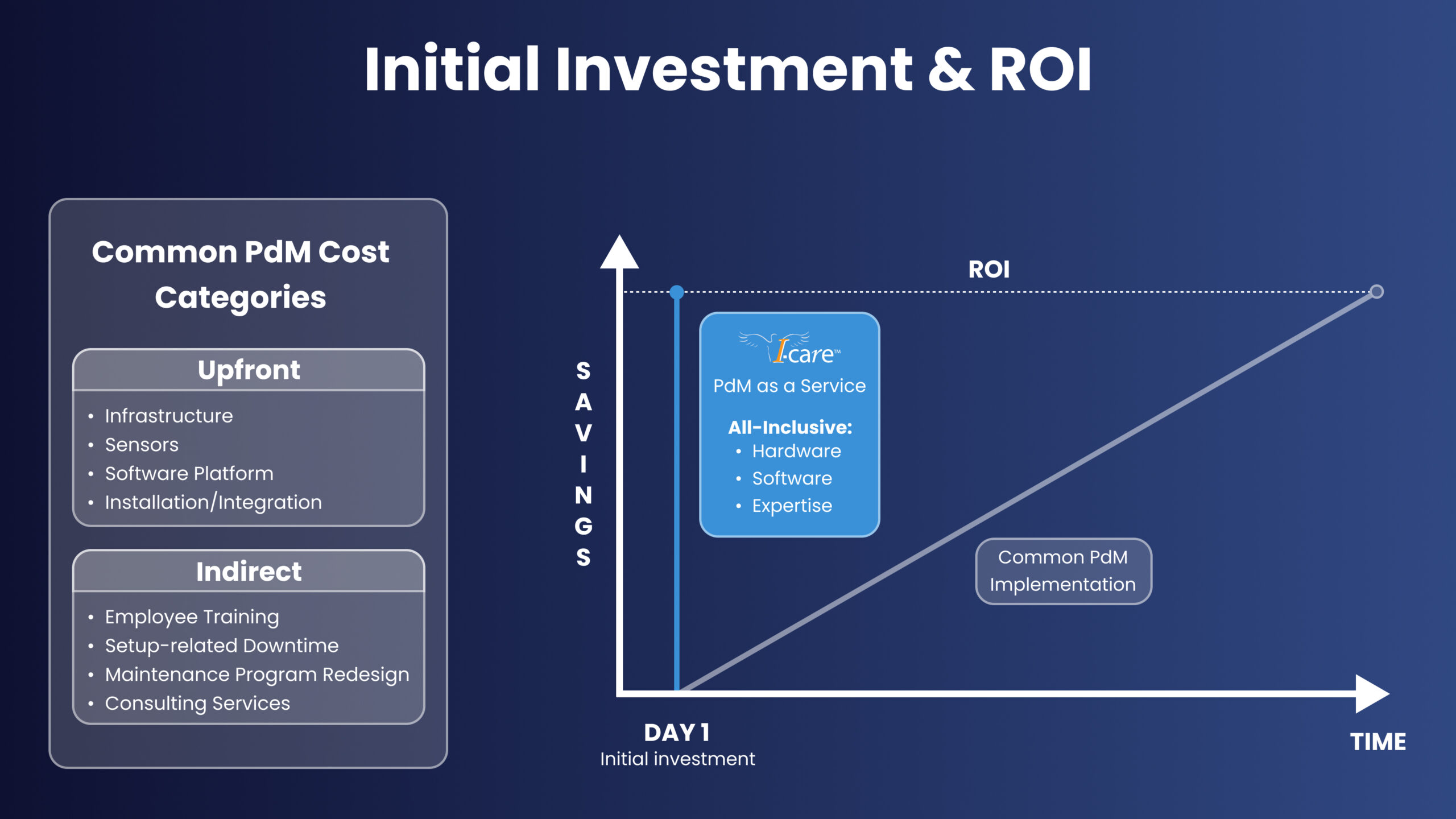

Initial Investment and ROI

Implementing a Predictive Maintenance program can require significant investments in hardware, software, infrastructure, and personnel. Typical cost categories include:

- Upfront costs: Sensors, software platform, infrastructure, and installation or integration services.

- Indirect costs: Employee training, maintenance program redesign, temporary downtime during setup, and external consulting or expertise.

While the upfront costs may seem significant, they can be mitigated by leasing equipment, using scalable cloud-based analytics software, selecting modular training programs, or subscribing to Predictive Maintenance as a Service bundles that include sensors, software, and expert analysis for a low monthly fee.

Predictive Maintenance is not just an operational expense; it’s a strategic investment. With the proper planning and execution, PdM delivers sustainable gains in reliability, efficiency, and operational performance.

Want All the Benefits of Predictive Maintenance Without the Upfront Cost?

At I-care, we refuse to let price stand between you and the power of Predictive Maintenance. That’s why we created Predictive Maintenance as a Service, our service model that skips the capital-expense hurdles, delivers ROI from day one, and scales on your terms. For a single monthly fee per sensor, you get an all-inclusive solution that seamlessly integrates hardware, software, and expertise. We install, maintain, and continuously upgrade everything, so you enjoy maximum uptime and actionable insights that boost yield across your sites.

Technical Expertise Requirements

Implementing and managing a Predictive Maintenance program is not just about having the right tools; it’s also about having the right people.

PdM success depends on specialized technical expertise and requires cross-disciplinary knowledge that bridges maintenance, analytics, and IT systems.

To cover these diverse skills, most successful PdM programs blend four complementary roles:

- Maintenance Technicians & Engineers (e.g., vibration, thermography, ultrasound): They install sensors, perform diagnostics, and execute maintenance interventions.

- IT/OT Integration Specialists: They establish and maintain secure connectivity between sensors, edge devices, software platforms, and enterprise systems, ensuring reliable data flow.

- Data Scientists or Analysts: They process and analyze raw asset health data, extract patterns, detect early warning signs, and predict potential failures using advanced analytics and machine learning models.

- Reliability Engineers: They interpret insights from condition monitoring and failure data to identify relevant failure modes and adapt asset strategies accordingly. Their role is to optimize maintenance plans, improve asset performance, and reduce operational risks.

Ready to Kick-Start Your Predictive Maintenance Program with Expert Support?

At I-care, we understand that many companies don’t have all these resources in-house. Our teams combine deep technical expertise with advanced tools and platforms to bridge skill and equipment gaps, accelerating your PdM deployment. Whether it’s condition monitoring, data analytics, or IT/OT integration, we’re here to help you build a high-performance Predictive Maintenance program.

Future of Predictive Maintenance

AI & Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are transforming Predictive Maintenance by applying advanced computational methods to analyze massive datasets, identify hidden patterns, and make highly accurate predictions about equipment health.

Machine learning algorithms continuously learn from historical and real-time data to identify patterns and evolving trends, refining their predictions over time. As they process more information, they become increasingly effective at recognizing anomalies, forecasting potential failures, and recommending or even automating the appropriate maintenance actions.

This evolution of PdM is referred to as Prescriptive Maintenance, where AI doesn’t just predict what might fail, but also recommends how and when to act.

Some examples of AI in PdM:

- Anomaly detection: AI flags deviations from normal equipment behavior that signal potential failure.

- Remaining Useful Life (RUL) prediction: AI models forecast how much longer a component can operate before failure.

- Failure mode classification: Classification algorithms determine likely causes behind abnormal patterns, labeling the problem type.

- Maintenance action optimization: Reinforcement learning or decision-tree models suggest the most cost-effective maintenance action.

- Multisensor correlation: AI combines signals from multiple sensors (e.g., vibration, temperature, pressure) to contextualize anomalies and support fault localization.

Ready to Future-Proof Your Maintenance with AI-Powered Predictive Insights?

At I-care, we combine advanced Artificial Intelligence with deep domain expertise (e.g., Pharmaceutical, Food & Beverage, Wind Energy, and Chemical Processing) to transform raw asset data into clear and actionable insights. Our AI continuously analyzes historical and real-time signals to detect anomalies, predict failures, and recommend timely actions, enabling your team to transition from reactive fixes to Predictive Maintenance.

Built as an open, interoperable software, our Predictive Maintenance platform plugs effortlessly with your existing systems (CMMS), ERP, and other enterprise systems, enabling connectivity across assets, technologies, and teams. We manufacture our own Wi-care™ wireless sensors, providing a fully integrated, end-to-end solution. Backed by thousands of clients in all industries, we bring a proven, global playbook. Whether scaling across multiple sites or just getting started, I-care delivers the resources and intelligence you need to future-proof your maintenance strategy.

IoT and Industry 4.0

The Internet of Things (IoT) refers to a network of interconnected physical devices embedded with sensors, software, and connectivity, enabling them to collect, exchange, and act on real-time data.

In the context of Predictive Maintenance, IoT plays a foundational role by enabling:

- Real-time asset monitoring through smart sensors that detect vibration, temperature, pressure, and other key indicators.

- Enhanced connectivity between machines, control systems, and maintenance platforms for seamless data flow.

- Cloud-based storage that enables timely analysis, early warnings, and faster decision-making.

- Remote monitoring and control, enabling maintenance teams to oversee and respond to asset health issues from any location.

These IoT capabilities establish the foundational “nervous system” of Industry 4.0. By continuously feeding rich, condition-based inputs into edge-compute and/or centralized platforms, they enable the next generation of industrial operations.

Industry 4.0 represents the fourth industrial revolution, integrating cyber-physical systems, automation, cloud computing, and data analytics to create intelligent maintenance and self-optimizing manufacturing environments.

Predictive Maintenance is a key pillar within the Industry 4.0 framework, and its capabilities are significantly enhanced by:

- Seamless integration into broader smart factories and connected ecosystems, where PdM interacts with Enterprise Resource Planning (ERP), Manufacturing Execution System (MES), and other enterprise systems.

- Using edge computing, cloud computing, and big data analytics to process sensor data faster and generate deeper operational insights.

- Automated maintenance decision-making, powered by AI platforms that predict failures and recommend or trigger corrective actions autonomously.

As IoT and Industry 4.0 technologies evolve, Predictive Maintenance benefits from ongoing advancements, becoming more precise, scalable, and integrated, laying the groundwork for truly autonomous and intelligent asset management.