Machinery Overview

The extraction fan removes hot air, smoke, and combustion gases generated inside large industrial ovens, ensuring safe and efficient ventilation.

It operates by creating a steady airflow that pulls exhaust from the oven chamber through a ducting system. This maintains the correct internal pressure, prevents overheating, and ensures a consistent baking or drying environment.

The extracted air is typically directed toward filtration or released safely outside, helping protect both equipment and personnel while supporting thermal efficiency.

Its power train comprises :

Motor: 120kW, 4-pole motor, VFD

Fan: ± 1200RPM

Monitoring Devices and Software Set-up

I-care reliability engineers placed Wi-care™ vibration sensors on the different assets to monitor the entire setup’s vibration, impact, and temperature. The engineers placed two vibration sensors on the motor and one on each fan bearing support to detect potential faults.

Once set up, Wi-care sensors send machinery health data to I-see™, I-care AI-powered analytics platform. Its role is to meticulously categorize the data points and identify whether they indicate healthy operation, a potential problem, or a critical alarm. The AI-generated insights are compiled into reports, providing a clear view of the complete assets’ health.

To bridge diagnostics with operations, I-see™ integrated with MVP One CMMS. The seamless connection enables I-see™ to automatically send its diagnostic reports and alerts to MVP One, where they trigger the scheduling of maintenance operations.

Detailed Analysis

Step 1 | Issue detection

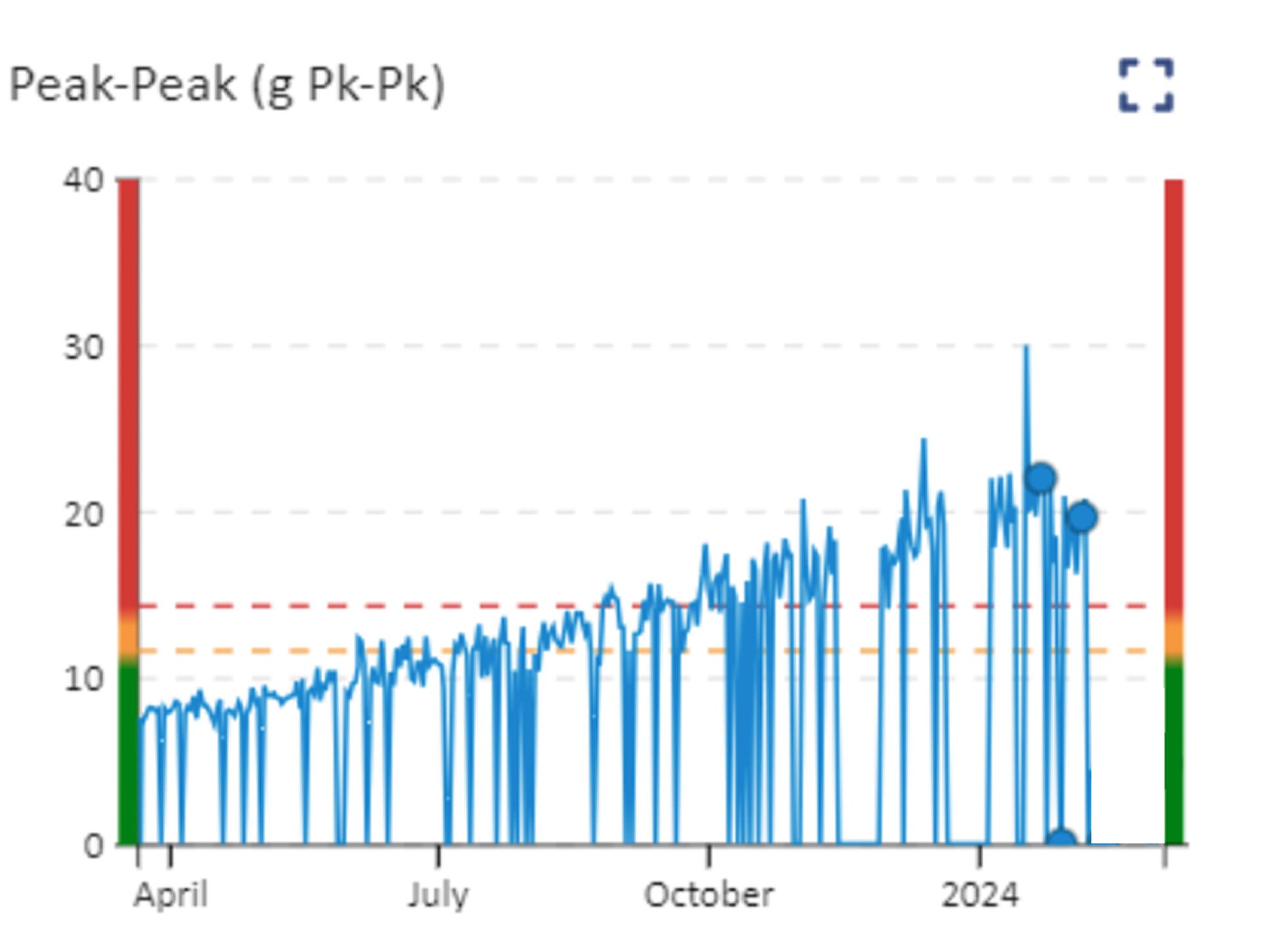

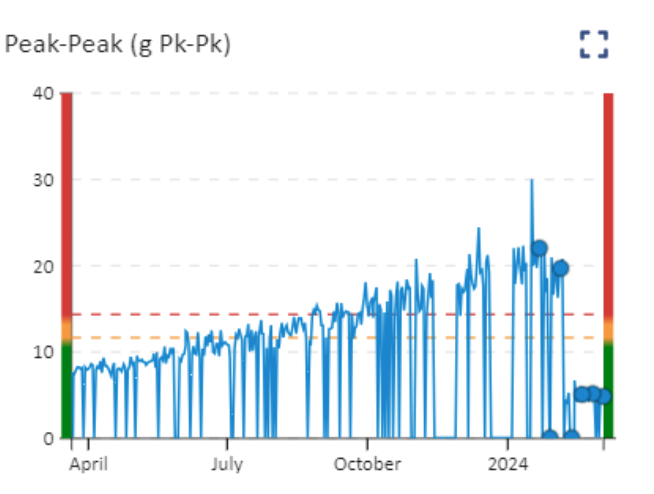

Several consecutive high readings were flagged in the I-see™ dashboard, indicating abnormal behavior and a potential issue with the motor fan.

This alert prompted an immediate, detailed analysis and a validation by a vibration expert.

Step 2 | Analysis

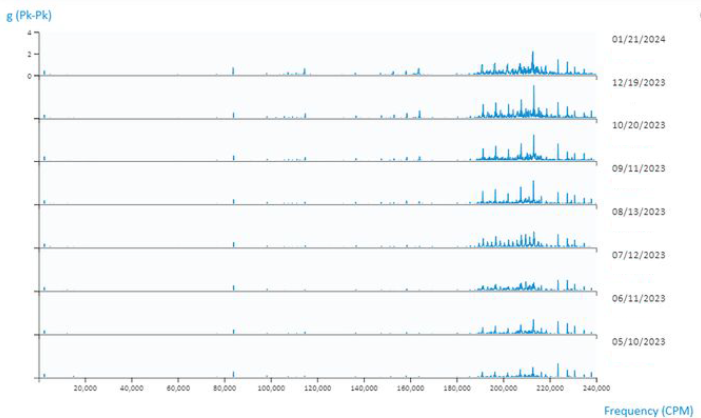

Motor sensor data revealed non-synchronous peaks in the spectrum, indicating a bearing defect.

The data showed an upward trend.

Step 3 | Recommendation through I-see™

Based on the analysis, the I-care engineer recommended the following action plan:

- Replace the motor (which is more cost-effective than replacing the bearing)

- Inspect the belts and sheaves for wear and replace if necessary

- Align the sheaves and properly tension the belts

Step 4 | Work order

The MVP One CMMS received information from I-see™, verified the spare parts availability for each issue, and scheduled maintenance strategically.

This proactive planning enabled the company to carry out interventions at the optimal time, reducing production downtime and preventing costly disruptions—while ensuring a safer working environment by minimizing the risk of unexpected equipment failures.

Step 5 | Replacement

The maintenance worker replaced the motor within days of the initial detection, preventing further damage and costly production failures.

Step 6 | Feedback loop and effectiveness

After replacing the motor, the worker documented the maintenance intervention and repair details directly within the MVP One platform. Thanks to the established integration, this information was then transferred to I-see™, enabling the monitoring system to update its internal asset history and contextualize sensor data with real-world maintenance actions.

I-see™ used this trigger to compare vibration levels before and after the intervention, which revealed a clear disappearance of the vibration anomaly—confirming the effectiveness of the corrective action.

Results

When Predictive Maintenance Pays Off — $80,000 Saved with I-care and MVP ONE

If the motor fan bearing fault had gone undetected, the plant would have faced an estimated complete production halt for eight hours. At a downtime cost of $10,000 per hour, the potential loss totaled around $80,000—excluding the additional risks of collateral damage and extended repair time.

Instead, the fault was caught early—thanks to I-care’s predictive maintenance approach combining Wi-care™ sensors and I-see™ diagnostics. Integration with MVP One ensured rapid execution. What could have been a significant disruption turned into a planned intervention, keeping production steady and avoiding costly surprises.

This case illustrates the strength of a fully connected maintenance ecosystem. I-care provides diagnostics that guide maintenance planning through MVP One. Once actions are completed, the feedback captured in MVP One loops back into I-see™, sharpening its predictive maintenance capabilities and making future diagnostics even more precise. This closed-loop flow transforms raw data into continuous improvement—powering a smarter, data-driven reliability strategy.

Learn About Our

Success Stories

Our Solutions Span All Assets,

Including Yours.

Are you ready to enhance your efficiency?