Machinery Overview

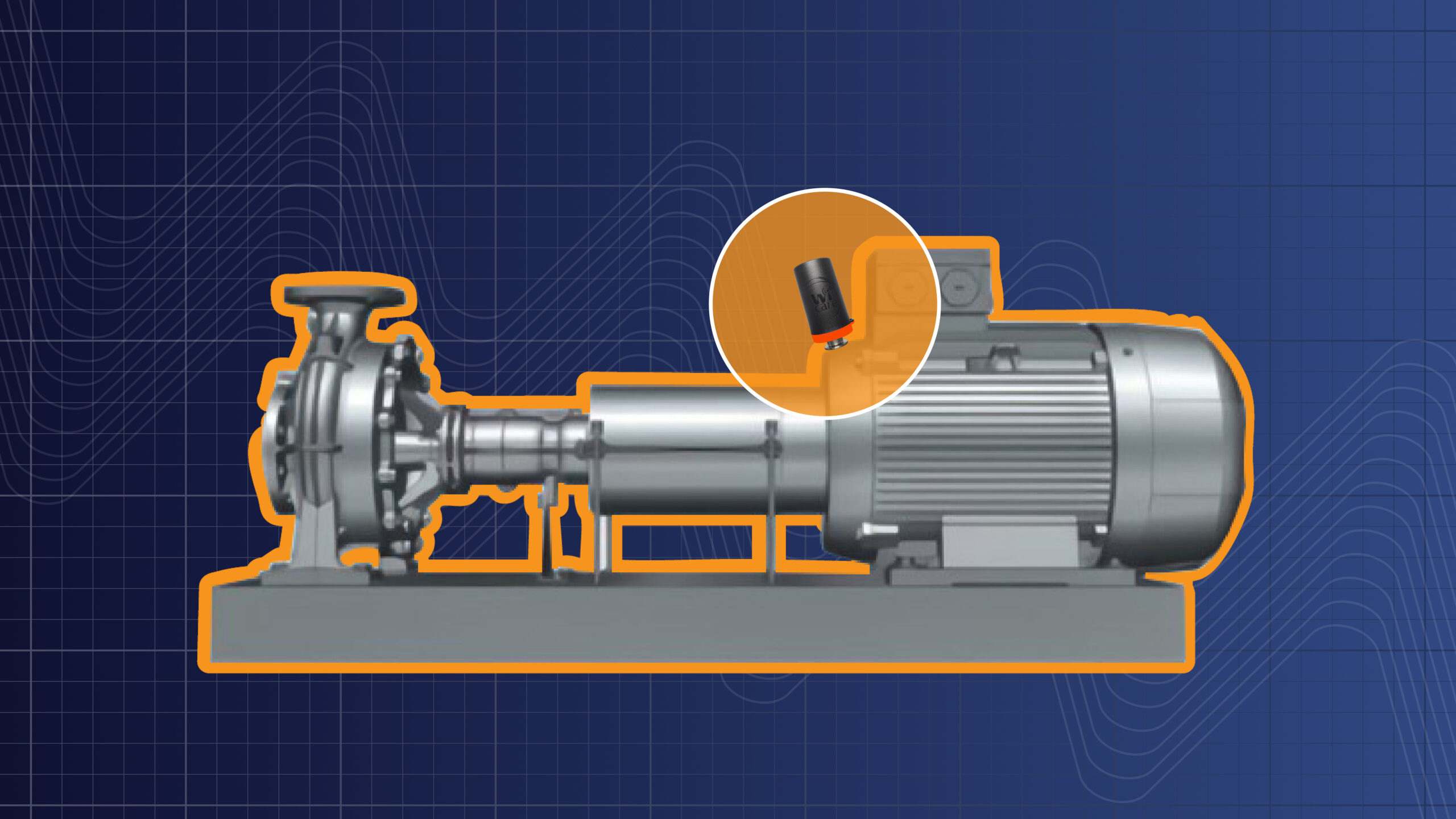

The circulation pump is a fixed-speed centrifugal pump driven by an electric motor. The motor and pump are connected by a coupling, which transmits torque while accommodating minor shaft misalignments. When the motor operates, it drives the pump’s impeller via the coupling, increasing the liquid’s velocity within the pump.

This kinetic energy is then converted into pressure, which pushes the fluid through the system.

Motor: 2980RPM, 30kW, 2-pole motor

Pump: Centrifugal, 6-vane impeller

Monitoring Devices and Software Set-up

The monitoring setup included Wi-care™ wireless triaxial vibration sensors installed on the electric motor. The focus of monitoring was on the motor, where conditions allowed the collection of precise and dependable data.

Once installed, the Wi-care™ sensors transmit machinery health data to I-see™, I-care’s AI-powered analytics platform. The platform automatically structures and processes incoming data, distinguishing between normal operating conditions, early signs of degradation, and critical alerts requiring immediate attention.

AI-generated insights are compiled into reports that outline asset health trends. Then, I-care analysts review these reports, validate the findings, highlight potential issues, and provide actionable recommendations, as detailed below.

Detailed analysis

Step 1 | Issue detection

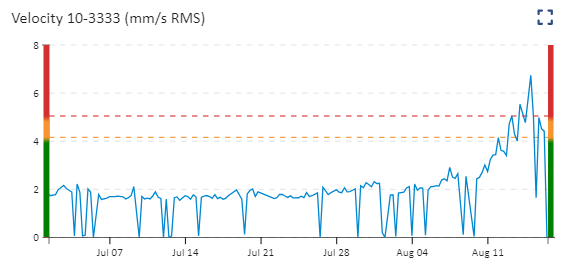

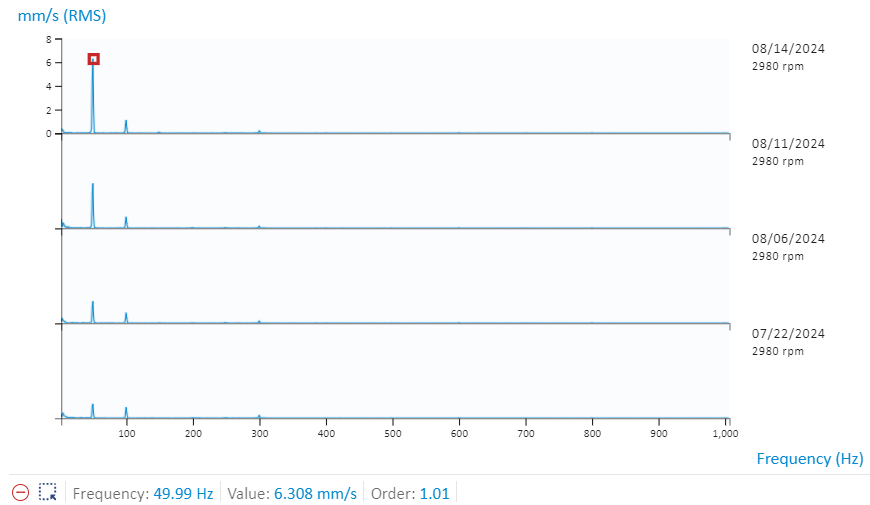

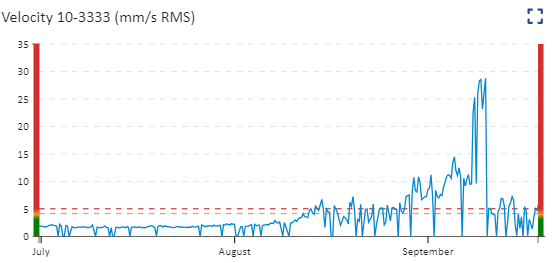

The I-see™ dashboard revealed a sharp increase in vibration levels. The spectrum showed elevated vibration at the 1X running speed, corresponding to the motor’s shaft rotation.

Step 2 | Analysis

I-care’s reliability engineer consulted the vibration spectrum and confirmed the issue. Since the peak was observed close to the coupling, the engineer first recommended a coupling inspection — a simple, non-intrusive verification step.

Step 3 | Inspection

During the inspection, the pump remained in operation while the engineer used a stroboscopic light to examine the coupling. Visible damage confirmed the source of the vibration.

Step 4 | Replacement

Leveraging the CMMS–I-see™ integration, a work order for coupling replacement was issued immediately.

Step 6 | Effectiveness

After replacing the coupling, a new baseline measurement was taken. Since the vibration signature had changed, the I-see™ alarm levels were reset to establish a new reference point. Subsequent monitoring confirmed that the defect was eliminated and the machine was operating normally.

Results

Prevented Breakdowns and Secured Performance

Without predictive maintenance (PdM), the customer would likely have faced unexpected pump stoppage, resulting in unplanned downtime, costly repairs, and production losses.

The customer noted that the root cause of this coupling failure was still under investigation. They reported accelerated mechanical deterioration on this type of coupling, with some failing within weeks. This makes periodic measurements insufficient and highlights the importance of I-care’s continuous monitoring solution.

Learn About Our

Success Stories

Our Solutions Span All Assets,

Including Yours.

Are you ready to enhance your efficiency?