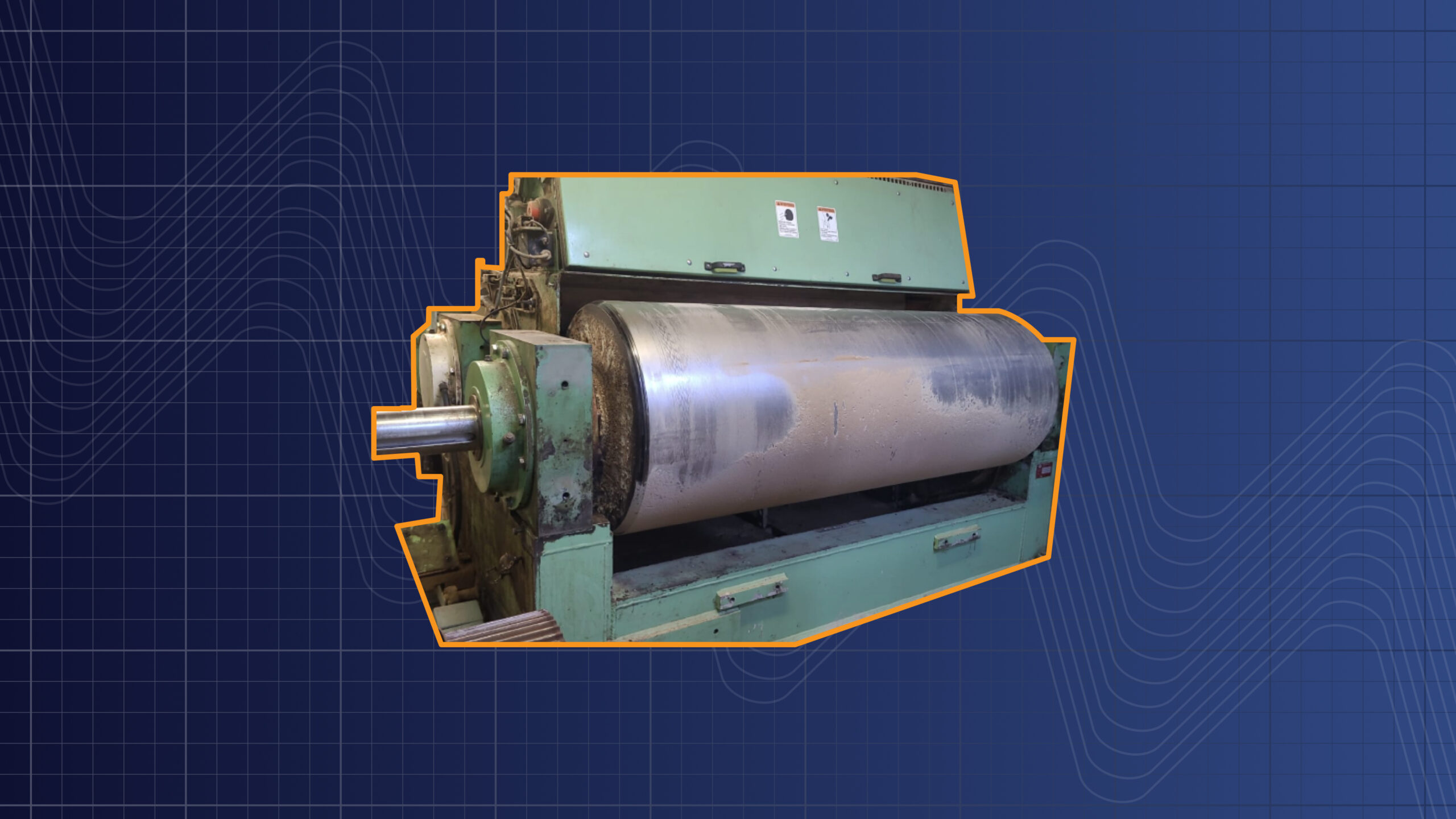

Machinery Overview

The monitored asset is a slow-speed rolling mill equipped with large roller bearings operating at just 268 RPM (4.47 Hz).

Due to its design and location, the machine cannot be assessed using offline vibration measurements, making continuous wireless monitoring essential for detecting early faults.

Slow-speed: 268 RPM (4.47 Hz)

Constraint: limited accessibility and safety restrictions

Monitoring Devices and Software Set-up

Wi-care™ G23 wireless vibration sensors were installed on the casing of the rolling mill, positioned as close as possible to the bearings despite limited accessibility. Because low-speed bearings generate weaker vibration signatures, sensor placement was critical.

All measurements were automatically transmitted to I-see™, I-care’s AI-powered analytics platform, where the data was processed and analyzed to track the machine’s condition and detect early signs of deterioration.

The insights generated by I-see™ are compiled into clear diagnostic reports that provide a complete overview of the health status. I-care analysts then review these reports to detect faults, diagnose potential issues, and provide actionable recommendations as outlined in the steps below.

Detailed Analysis

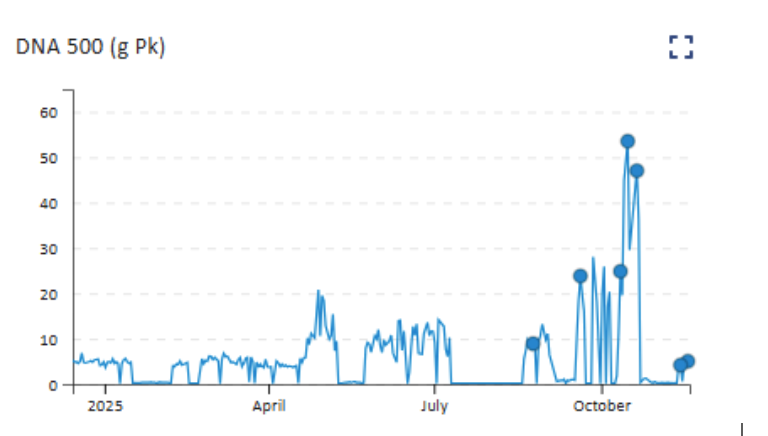

Step 1 | Issue detection

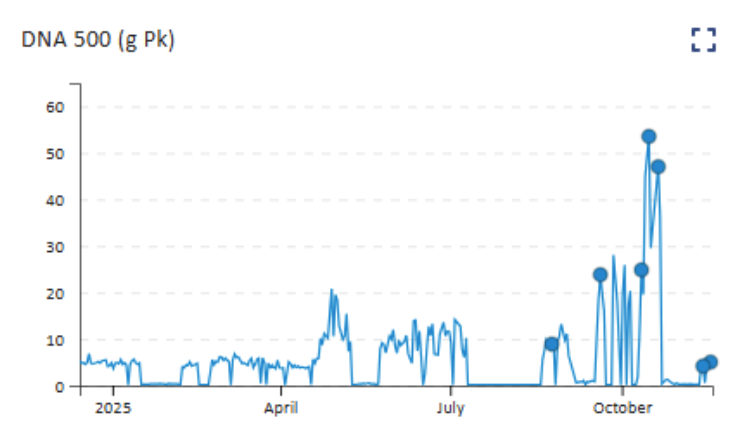

I-see™ detected abnormal behavior on the roller bearing, highlighted by several consecutive high values in the high-frequency I-DNA readings. This technique is designed to reveal weak impact signals that occur in slow-speed bearings—signals that conventional vibration measurements often fail to capture.

The alert, automatically flagged by I-see™, triggered an immediate, in-depth investigation by one of I-care’s vibration experts, ensuring rapid assessment of the issue.

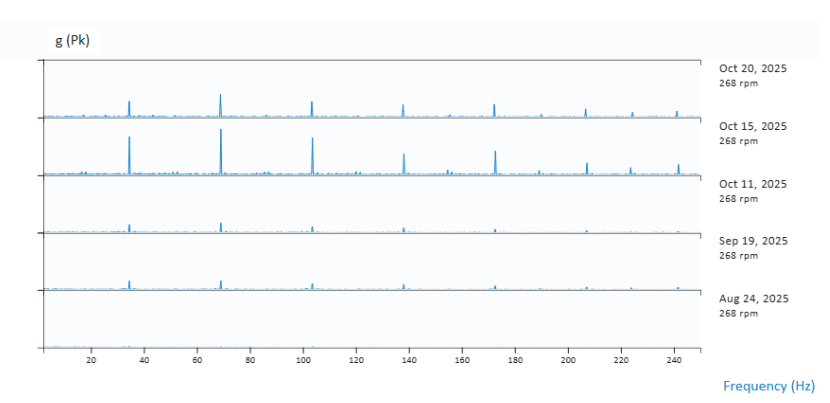

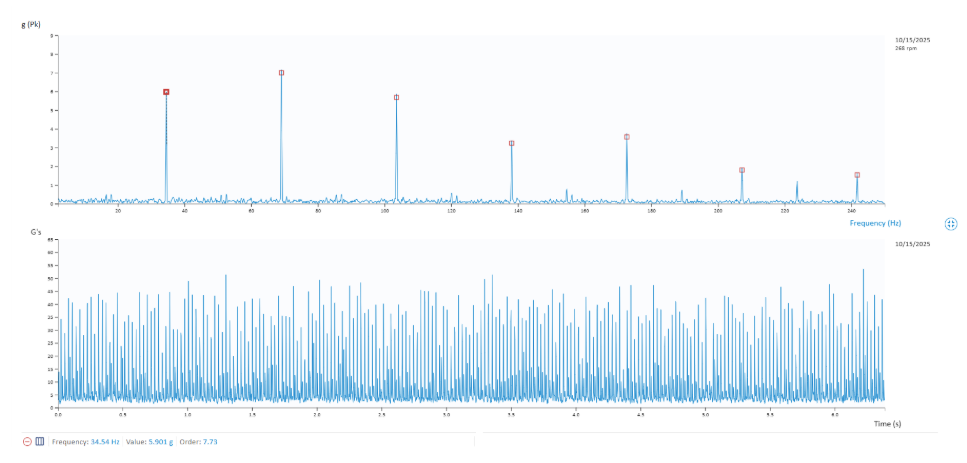

Step 2 | Analysis

Through his analysis of the graphs, the expert identified a clear BPFO bearing frequency in the spectrum and significant impact signatures in the waveform – BPFO at 7.719x shaft speed (Timken 23248 EMB).

Step 3 | Recommendation & inspection

Given the suspected bearing damage indicated by the vibration signals, the expert recommended an on-site inspection.

The I-care expert found significant damage in two areas, and hardened material circulating inside the bearing had also damaged the rollers.

Step 4 | Replacement

Since the repair could not be performed on site, the roller was extracted and sent to an external company for repair.

The Wi-care™ sensors were transferred to a backup roller already available for this type of situation, enabling the swap at a strategic moment and avoiding production losses.

Step 5 | Effectiveness

The replacement roller operated normally and showed no signs of defects.

Results

When Slow-Speed Monitoring Pays Off — More Than $500,000 Saved with I-care

The vibration data and I-see™ analysis revealed a developing BPFO defect on the slow-speed roller bearing. An on-site inspection confirmed significant damage to the raceway and rollers, validating the diagnostic findings.

The faulty roller was removed and repaired externally, while Wi-care™ sensors were immediately transferred to the backup roller to maintain monitoring continuity.

By detecting the issue early, the customer avoided up to 3 weeks of reduced production, an estimated $504,000, and the associated safety risks.

Learn About Our

Success Stories

Our Solutions Span All Assets,

Including Yours.

Are you ready to enhance your efficiency?