For decades, technicians sprayed soapy water on compressed-air lines, waiting for bubbles to betray a leak. Today, an ultrasonic detector finds the leak in seconds: no bubbles, no downtime, no doubt.

This illustrates the evolution from traditional “tricks” to advanced maintenance practices, highlighting the importance of Predictive Maintenance (PdM), which goes far beyond simple time-based maintenance, involving accurate assessments to detect equipment issues before they escalate into significant faults.

Ultrasound Analysis in Predictive Maintenance solutions is a powerful Condition Monitoring technique used to detect hidden defects by analyzing high-frequency sound emissions. As a key element of Predictive Maintenance services, it enables the detection of issues, often long before equipment failures occur, thus reducing unplanned downtime and associated cost. By delivering real-time acoustic data, Ultrasound Analysis complements other predictive technologies, adding an extra layer of defense to maintenance decision-making across the maintenance team.

This article serves as a guide to Ultrasound Analysis, exploring how it works, the specific tools it uses, and its integration into a Predictive Maintenance software. Additionally, this article covers the specific types of anomalies detectable through this method, commonly monitored assets, and both the advantages and limitations of using Ultrasound. It also highlights real-world examples and practical benefits of applying this powerful technique in various industries.

Table of Contents

What Is Ultrasound Analysis?

Ultrasound Analysis is a powerful, non-invasive Condition Monitoring technique that measures and analyzes high-frequency sound emissions (typically 20 kHz – 100 kHz, both airborne and structure-borne) generated by mechanical, fluid-system, and electrical equipment during operation.

This method is widely used in Predictive Maintenance. Its role is to detect high-frequency acoustic anomalies long before they evolve into failures, complementing the 5 other Condition Monitoring techniques: Vibration Analysis, Infrared Thermography, Oil Analysis, Motion Magnification, and Motor Circuit Analysis.

All operating equipment produces some background ultrasonic noise, but faults such as compressed‑air leaks, bearing friction, steam‑trap failure, or electrical discharge create distinctive high‑frequency hissing, clicking, or bursting patterns that stand out from the normal acoustic signature.

Within Predictive Maintenance, technicians perform ultrasound inspection using a handheld ultrasonic detector, directional microphone, or permanently mounted transducer to pinpoint issues long before they cause energy loss, component damage, or unplanned downtime.

What Does Ultrasound Analysis Aim to Detect?

Ultrasound Analysis detects a wide range of ultrasonic anomalies that threaten asset reliability and operational performance. These are early symptoms of potential failure, allowing earlier intervention and more effective maintenance. The key benefit lies in this early failure detection through abnormal ultrasonic signatures in acoustic waveforms or real-time sound recordings, before problems escalate into major breakdowns.

Each fault mode generates a distinct ultrasonic pattern, often visible as amplitude spikes, tonal shifts, or rhythmic bursts in the acoustic signal. These acoustic waves act as early indicators of symptoms of underlying issues, enabling fault diagnosis and trending over time.

Behind every ultrasonic signal lies a physical phenomenon: turbulent flow in compressed air lines produces broadband noise, friction between moving parts raises high-frequency amplitudes, cavitation or impacts generate sharp bursts, and partial electrical discharges emit characteristic crackling or buzzing.

Ultrasound Analysis uses sensitive ultrasonic instruments to capture high-frequency sound emissions, and when applied through ultrasonic inspection, it serves as an early defense mechanism to pinpoint where abnormal acoustic energy signals a potential failure, often at an earlier stage than vibration, temperature, or pressure changes.

Specifically, Ultrasound Analysis can detect:

- Air and gas leaks: Continuous high-frequency hissing or whistling sounds, typically found at fittings, couplings, valves, pipe joints, or along a tube

- Bearing wear and lubrication issues: Rhythmic clicking, crackling, or rising dB levels, indicating early-stage pitting, metal-to-metal contact, insufficient lubrication, or incorrect grease application.

- Valve and steam trap failures: Erratic or non-cycling ultrasonic patterns that reveal blockage, leakage, or stuck components.

- Electrical discharges: Intermittent or sustained high-frequency emissions such as corona (faint hiss), tracking (sizzle), or arcing (sharp popping).

- Mechanical impacts: Broadband or pulsed ultrasonic bursts caused by gear-tooth collisions, pump cavitation, or developing cracks, often presenting as irregular peaks or bursts.

Which Assets Are Typically Monitored with Ultrasound Analysis?

In practice, Ultrasound Analysis is applied to a wide range of mechanical equipment, fluid systems, and electrical assets across industrial and utility environments. Its effectiveness is particularly evident when monitoring equipment where high-frequency sound emissions are a reliable indicator of condition.

Even minor variations in acoustic signatures can reveal emerging deterioration, allowing maintenance teams to intervene before asset health, performance, safety, or efficiency are compromised.

Typical assets monitored with Ultrasound Analysis include:

- Steam traps (mechanical, thermodynamic, thermostatic)

- Pumps (centrifugal and positive displacement)

- Bearings and gearboxes

- Compressed air and gas lines (pipes, couplings, quick-connects)

- Electrical switchgear and cabinets

- Transformers and high-voltage insulators

How Does Ultrasound Analysis Work?

Ultrasound Analysis is a systematic process comprising the following five detailed steps:

- Deployment via handheld detectors or permanently mounted ultrasonic probes.

- Data collection of high-frequency acoustic emissions (20 kHz – 100 kHz) from components such as bearings, valves, steam traps, or leak points.

- Data transformation using heterodyning, envelope detection, and spectral analysis.

- Baseline comparison of measurements against known-good ultrasonic signatures under matching load and environmental conditions.

- Fault-signature mapping by correlating acoustic patterns with a library of known failure modes.

Step 1: Deployment Modes

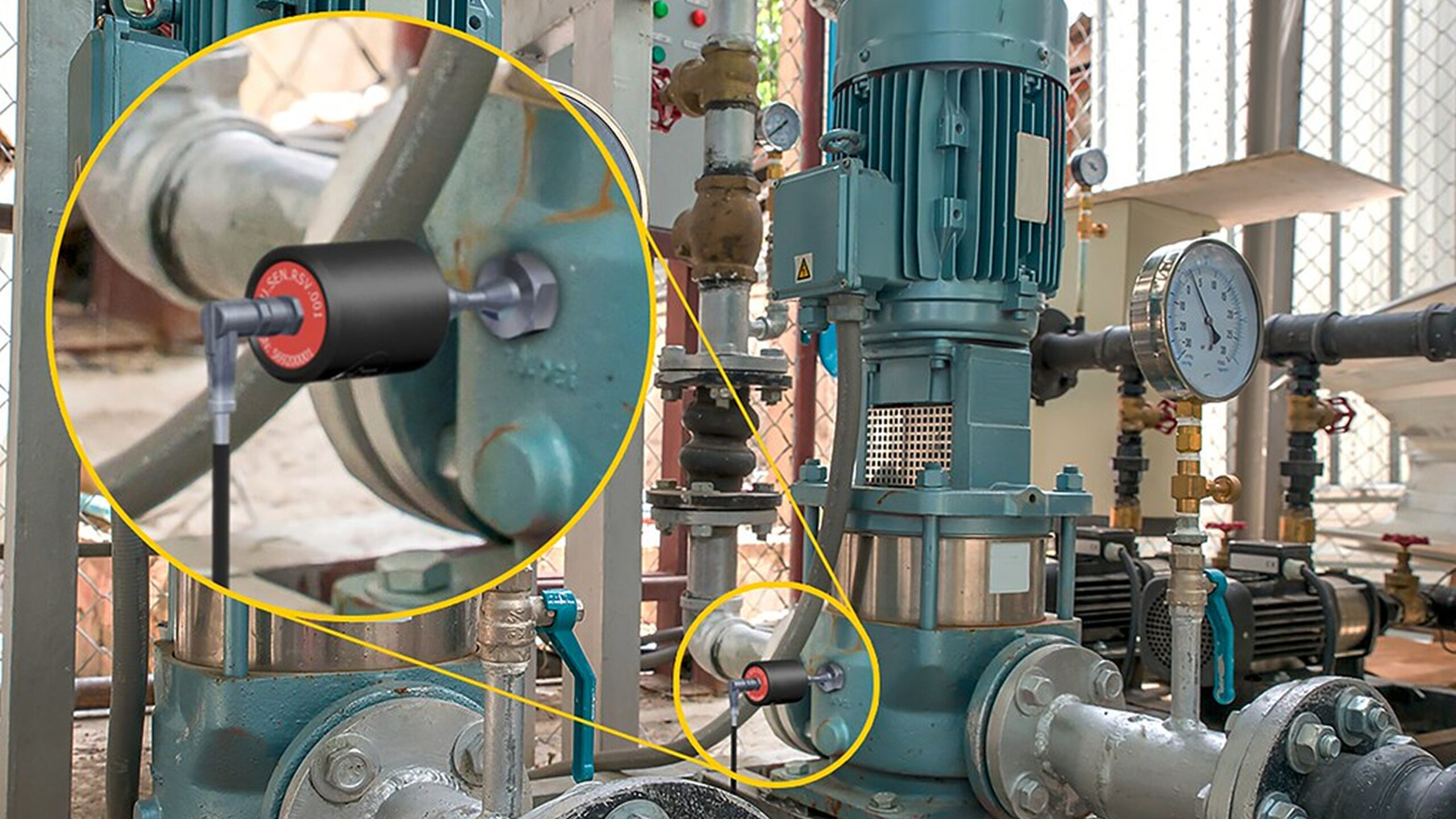

Ultrasound Analysis can be deployed in two modes: handheld mode and fixed-probe mode, depending on asset criticality, accessibility, and the required frequency of monitoring.

- Handheld mode: In this mode, technicians use a portable ultrasonic detector equipped with interchangeable probes (airborne or contact). It is commonly used for routine inspections on bearings, valves, seals, steam traps, or electrical components. Handheld testing is ideal for detecting localized faults such as air leaks, arcing, or friction-based wear, providing the maintenance team with flexibility when continuous monitoring is not available. During operation, technicians can simply listen in real time via headphones and capture spot measurements for trending or diagnostic review, enabling close and precise acoustic detection.

- Fixed-probe mode: In this mode, ultrasonic transducers are permanently mounted on critical assets to provide continuous monitoring. It is typically applied to assets that are either process-critical, such as pressurized lines, steam traps in essential systems, or difficult to access manually, like remote or enclosed bearings. These IoT ultrasonic sensors stream data either directly to a Predictive Maintenance (PdM) platform or through an intermediate condition monitoring system. In both cases, automated detection of decibel spikes or acoustic anomalies can trigger alerts, reducing the manual work usually required from inspectors and enabling early intervention when deviations from baseline patterns occur. By reducing the need for manual inspections, fixed-probe mode enables early alerts whenever ultrasonic signatures deviate from baseline patterns, ensuring timely intervention and greater reliability.

Step 2: Data Collection

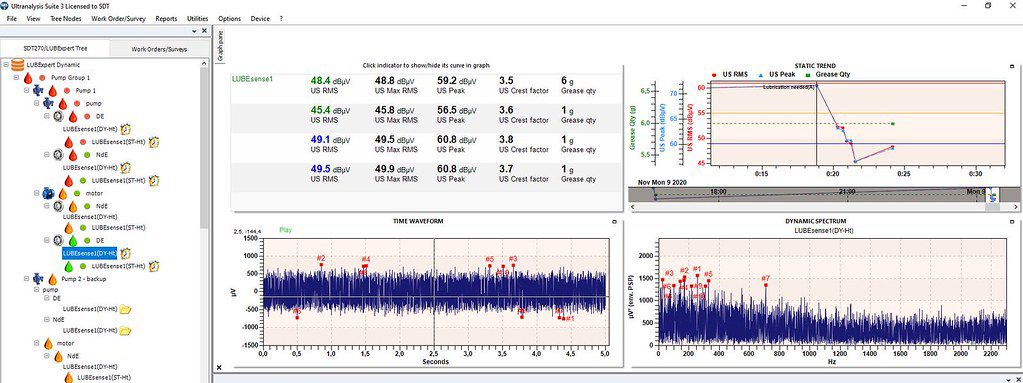

Ultrasound Analysis captures high-frequency sound waves (typically in the 20 kHz – 100 kHz range) that are above the human hearing threshold. For example, SDT ultrasonic detectors are commonly set to 38.7 kHz, which corresponds to the point of highest sensor sensitivity for their standard probes.

Data is collected using ultrasonic sensors, which can include both contact probes for structure-borne signals and airborne sensors for leak and electrical detection. Contact probes are placed on the bearing housing, valve body, steam trap casing, or other accessible surfaces to detect internal friction, turbulence, or impact events. Airborne sensors, including directional microphones or parabolic dishes, are positioned at a distance to capture ultrasonic emissions from pressurized leaks or electrical faults.

Measurements, or acoustic readings, are typically carried out while the equipment is running, without requiring a shutdown, allowing inspectors to gather data under real operating conditions. The instruments, whether handheld detectors or fixed ultrasonic sensors, measure and record each ultrasound signal, including its amplitude (usually expressed in dB or dBµV, depending on the device) and qualitative sound characteristics such as intensity, tone, and repeatability. This dual capture of quantitative and qualitative data ensures that even subtle anomalies can be identified early, enabling the team to act on predictive insights before functional failures occur.

Step 3: Data Transformation

Raw ultrasonic signals are typically very high-frequency and cannot be interpreted directly by human hearing or standard visual analysis. To make them usable, a process called heterodyning is applied, which shifts ultrasonic frequencies into the audible range. This allows operators to simply listen to the signal in real time through headphones or speakers, transforming otherwise imperceptible sounds into recognizable acoustic cues.

At the same time, the ultrasonic instrument records key features, such as decibel level, waveform shape, and distinctive sound characteristics of the current signal. Advanced signal-processing techniques such as envelope detection or demodulation are also applied to extract the amplitude envelope of the signal, thereby improving clarity when noise overlaps with weak fault signatures. This is particularly useful for highlighting repeating impact patterns, for example, in bearings where defects cause rhythmic pulses that are otherwise hidden in raw data.

The processed information is then presented visually in the time domain as waveforms, spectral plots, or trend graphs, depending on the capabilities of the monitoring tool. By combining both qualitative assessment (listening to the heterodyned audio) and quantitative analysis (visual data plots), technicians and PdM engineers can accurately identify and classify fault signatures long before they evolve into critical failures.

Step 4: Baseline Comparison

Each ultrasonic measurement point is assigned a baseline profile that represents the normal decibel level and signal characteristics of the asset under healthy operating conditions. These baselines are usually established during commissioning or during a period of known-good operation, and they must be recorded under the same load, RPM, and environmental conditions to ensure accuracy.

When new measurements are taken, they are compared against this baseline. The analysis examines current dB values, waveform repeatability, and characteristic changes in the heterodyned sound to identify any abnormal increases or changes.

Key warning signs include a noticeable rise in decibel levels, the emergence of new impact patterns, or subtle shifts in the sound’s texture that indicate progressive asset deterioration. These deviations are strong indicators of developing faults such as bearing degradation, steam trap failure, or air leaks, allowing technicians to intervene before the issue escalates into a costly breakdown.

Step 5: Fault-Signature Mapping

Once ultrasonic data is collected, transformed, and compared against baseline profiles, analysts interpret specific sound patterns and signal characteristics in relation to known fault types. Different failure modes generate unique ultrasonic signatures that can be identified through changes in amplitude, waveform behavior, and heterodyned sound playback.

In Ultrasound Analysis, common fault signatures include:

- Continuous high-frequency hissing is usually associated with pressurized air, gas, or vacuum leaks.

- Intermittent or sustained electrical hissing or buzzing is often associated with corona discharge, arcing, or tracking in high-voltage systems.

- Rhythmic pulses or periodic clicking are detected in structure-borne measurements and linked to mechanical defects such as bearing pitting, lubrication failure, or gear tooth impacts, often appearing at an early stage of degradation.

- Sharp bursts or irregular transient spikes are associated with steam trap malfunctions, cavitation, or valve leakage.

Trained operators or automated diagnostic systems compare ultrasonic waves and their characteristics, such as amplitude, frequency content, and repetition patterns, against known fault libraries tailored to the asset type and operating context, to spot early symptoms of potential failure. This structured mapping process, often supported by audio playback and visual trend plots, enables precise identification of fault-related deterioration and timely prioritization of corrective actions.

What Tools Are Used in Ultrasound Analysis?

Hardware Tools

Handheld Ultrasonic Detector

A Handheld Ultrasonic Detector is widely used for route-based inspections across mechanical, fluid, and electrical assets. This portable device, often shaped like a gun, is equipped with an onboard display, a headphone jack, and built-in data logging capability.

Its versatility comes from interchangeable probes, which enable operators to adapt the detector to different applications. An airborne sensor is typically used to detect leaks and electrical discharges, while a contact probe is applied directly to components such as bearings, valves, or steam traps to capture structure-borne signals. For situations requiring inspection at greater distances, such as overhead pipework or high-voltage switchgear, directional microphones or parabolic attachments provide enhanced airborne detection. Modern models, such as the SDT340 and the SDT Flexible Airborne Sensor, are examples of advanced ultrasound equipment that combine portability with advanced detection features, showcasing how ultrasound technology has become indispensable in predictive maintenance programs.

Fixed Ultrasonic Transducer

A Fixed Ultrasonic Transducer is permanently mounted on critical equipment to provide continuous ultrasonic testing and monitoring of acoustic emissions. It is typically installed on components such as bearing housings, gearboxes, or pressurized lines, where ongoing surveillance is essential to detect early signs of wear or leakage. Like other ultrasonic testing instruments, this transducer is usually connected directly to condition monitoring systems, allowing real-time data streaming, automated alerts, and long-term trend analysis. By ensuring uninterrupted monitoring, it reduces the reliance on manual inspections and improves the reliability of fault detection. A widely used example is the SDT CONMON Sense Sensors, which integrates seamlessly with predictive maintenance platforms to deliver continuous acoustic insight.

Software Tools

Ultrasound Data Management and Analysis Platform

Ultrasound data management and analysis platform is used to log, store, and visualize inspection data over time, providing both historical context and real-time insights into asset health.

This software solution can store each inspection as a digital file, displaying outputs such as trend graphs, time waveforms, heterodyned audio playback, spectrograms, and even acoustic imaging, enabling in-depth fault analysis beyond what is possible in the field. It also allows technicians to compare new measurements against baseline thresholds and automatically generate detailed reports for maintenance records. Many platforms support seamless integration with Predictive Maintenance systems, CMMS, or EAM tools, often leveraging IoT connectivity to ensure that anomalies detected by ultrasonic sensors are directly linked to actionable maintenance workflows within a structured monitoring program. A key example is the SDT Ultranalysis Suite (UAS), which combines advanced analysis capabilities with full integration into reliability programs.

How Does Ultrasound Analysis Integrate with a Predictive Maintenance Platform?

Ultrasound Analysis data, whether captured through handheld detectors during route-based inspections or streamed continuously from IoT ultrasonic sensors, feeds into the PdM platform (e.g., I-see software).

Once uploaded to the PdM platform, each acoustic dataset is normalized and automatically tagged with relevant asset metadata. The platform then processes the ultrasonic signals through a structured analysis workflow, including:

- Charting each new acoustic reading and pattern trend against historical baselines to detect gradual degradation, comparing current readings such as rising dB levels or changes in heterodyned audio quality.

- Applying anomaly-detection rules or machine learning models to identify emerging friction, leakage, or electrical discharge signatures.

- Classifying ultrasonic anomalies by fault type, including bearing wear, steam trap failure, air or gas leaks, motor deterioration, and electrical arcing.

- Triggering alerts whenever thresholds or pattern-deviation rules are breached, ensuring early notification of developing issues.

- Suggesting corrective actions or generating work orders in CMMS or ERP systems to enable timely, prioritized interventions and implement them within standard maintenance workflows.

What Are the Advantages of Ultrasound Analysis?

By revealing otherwise undetectable acoustic anomalies instantly and reliably, Ultrasound condition monitoring stands apart with four key advantages.

The first one is its ability to pinpoint microscopic leaks in compressed air, vacuum, steam, or gas systems with unmatched sensitivity. This makes it a powerful tool to help reduce energy losses and improve overall system efficiency and production efficiency.

Another major strength of this technology is its effectiveness in extremely noisy environments. Unlike methods such as Vibration Analysis or conventional sound-level monitoring, which can be affected by ambient noise and require good mechanical coupling, Ultrasound Analysis isolates high-frequency signals, allowing anomalies to be detected even in challenging industrial conditions.

Ultrasound Analysis also provides immediate, real-time audio feedback. By listening to heterodyned signals through headphones, inspectors can confirm and localize faults instantly on critical machines, which helps speed up inspections.

Finally, ultrasound excels at detecting early-stage electrical discharges such as corona and tracking, as well as more severe events like arcing, along with frictional anomalies in bearings, motor shafts, and other rotating components. These issues often remain invisible to Vibration Analysis and are usually detected too late by Infrared Thermography, giving Ultrasound Analysis a decisive edge in early fault detection and making it a valuable tool in a predictive maintenance program.

How Many Hidden Anomalies Are Draining Your Assets Unnoticed?

Air leaks, steam trap failures, bearing friction, or electrical discharges often remain unnoticed until they waste energy, degrade equipment, or force costly unplanned downtime.

With I-care’s ultrasound Analysis services, these hidden anomalies are detected early, whether through handheld inspections or continuous IoT monitoring, allowing maintenance teams to act before failures occur and energy losses accumulate.

Turn unheard anomalies into actionable insights.

What Are the Limitations of Ultrasound Analysis?

While Ultrasound Analysis is a valuable tool across mechanical, fluid, and electrical applications, it has certain limitations that affect diagnostic accuracy:

- Detects only faults emitting high-frequency sound, making the technique ineffective for silent or low-frequency issues.

- Depends heavily on operator skill, as accurate differentiation between normal and abnormal ultrasonic signals requires training and experience.

- Offers limited penetration depth, restricting effectiveness in detecting deeper internal mechanical faults.

- Requires direct line-of-sight or clear acoustic pathways, as solid barriers or heavily enclosed assets significantly reduce performance.

Real-World Example of Usage

In a chemical processing plant, handheld ultrasonic detectors were used for ultrasound testing of steam traps across a network of heat exchangers. Using contact probes, technicians were able to measure erratic hissing bursts, a signature of live steam leakage from traps that were no longer cycling correctly.

The recordings were uploaded to the PdM platform, where trend analysis compared decibel levels and sound patterns against historical baselines. The system automatically flagged the anomaly, indicating failed open traps wasting live steam.

Maintenance teams were able to schedule a targeted shutdown to replace the defective traps before they caused costly downtime. The early detection at this stage eliminated unnecessary energy waste, identified leakage at a compressor valve, prevented water hammer risk in the piping system, and restored optimal heat exchanger and motor performance, safeguarding equipment health while protecting production efficiency and plant stability.

Necessary Skills and Training

Ultrasound Analysis demands a skill set that extends from basic acoustic inspections to more advanced signal interpretation, depending on the depth of application.

Skills Needed

Ultrasound Analysis requires a basic to intermediate level of expertise, depending on whether the focus is on routine inspections or advanced diagnostics. At a basic level, inspectors need a solid understanding of acoustic principles, signal behavior, and the proper use of ultrasonic detectors, whether airborne sensors for leaks and electrical discharges or contact probes for bearings, valves, and steam traps.

They must be able to perform consistent measurements, listen to heterodyned signals through headphones, and combine findings with a visual inspection when required to recognize common fault sounds such as leaks, arcing, or bearing friction. With this foundation, technicians can reliably carry out tasks such as leak detection, steam trap testing, and basic condition assessments after completing only introductory training.

More advanced analysis and diagnostics require a more profound knowledge of ultrasonic waves and their behavior, envelope detection techniques, and how dB trends change with machine RPM over time. Skilled analysts must be able to distinguish between normal and abnormal signal profiles, correlate specific patterns with fault types, evaluate current conditions (e.g., bearing degradation vs. lubrication issues), and use specialized software to interpret waveforms and spectrograms. At this level, effective fault diagnosis relies not only on technical knowledge but also on contextual awareness of asset operating conditions. To reach this expertise, practitioners need formal certification and extensive field experience across a variety of equipment types.

Training

Is your team struggling to leverage ultrasound insights?

SDT Ultrasound offers a complete certification path to help teams master this technology, from the Level I and II Ultrasound Certification and ISO CAT I Ultrasound Certification courses to the advanced Power User program and specialized Sherlog Hatch Cover.