Vibration Analysis vs. Ultrasound: Which One Should You Use for Your Rotating Assets

Vibration analysis as a means to monitor the condition of rotating equipment has been widely used in industry for many years. The appearance of portable digital analyzers by the end of the 1980s and the rapid increase in performance and speed in the early 1990s forever changed the way the world performed maintenance. By the end of the 20th century predictive maintenance based on vibration measurements was a well-established practice and the common approach in most large production facilities. Vibration analysis indeed provided a trusted way to detect a wide range of mechanical and – to a lesser extent – electrical defects and had sufficiently proven its added value. But some skepticism remained and in certain cases, rightfully so. Poor lubrication in roller bearings often remained undetected until the grease pump could no longer bring much relief and monitoring bearing conditions in low-speed applications also proved to be a particular challenge. Enter Ultrasound, a good alternative to vibration measurements in those cases. By trending measured decibels (dB) values and ‘listening’ to the signals after transformation into an audible signal, high-frequency ultrasound provides a reliable and efficient way for lubrication monitoring and can also provide invaluable information regarding the condition of a low-speed bearing. Why did ultrasound often provide better results in those two cases versus what could be obtained with vibration analysis? The explanation is not so difficult to find. Ultrasonic sensors measure signals in a frequency range between 20kHz and 40kHz. Lubrication issues in a roller bearing will generate increased friction and will indeed generate a lot of energy in this high-frequency band. In low-speed applications, bearing defect monitoring mostly relies on the detection of ‘stress waves’, again primarily generating very high-frequency signals. Vibration analysis on the other hand will rely mostly on waveform and spectral analysis. The FFT spectrum allows the analyst to relate specific bearing defect frequencies to the vibration signature, but the frequency range used for these standard FFT spectra rarely exceeds 5kHz, a range where damaged low-speed roller bearings will generate very limited energy, and also lubrication issues will not show much information until it’s far too late. True, FFT spectra using envelope techniques did provide a better way to analyze high-frequency signals, but the digitization of the analog envelope signal (as illustrated in Figure 1) still prevented proper detection of very high-frequency signals. Figure 1 shows the inability of the sampling process to detect the short envelopes resulting from rolling elements creating stress waves when passing a defect in a low-speed bearing.

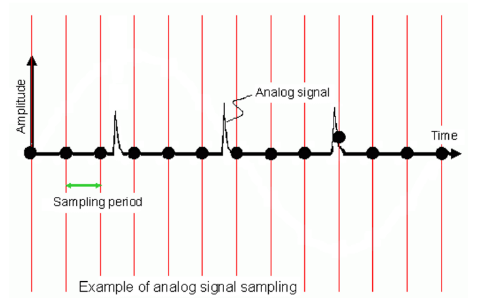

Vibration analysis on the other hand will rely mostly on waveform and spectral analysis. The FFT spectrum allows the analyst to relate specific bearing defect frequencies to the vibration signature, but the frequency range used for these standard FFT spectra rarely exceeds 5kHz, a range where damaged low-speed roller bearings will generate very limited energy, and also lubrication issues will not show much information until it’s far too late. True, FFT spectra using envelope techniques did provide a better way to analyze high-frequency signals, but the digitization of the analog envelope signal (as illustrated in Figure 1) still prevented proper detection of very high-frequency signals. Figure 1 shows the inability of the sampling process to detect the short envelopes resulting from rolling elements creating stress waves when passing a defect in a low-speed bearing.

Figure 1. ‘Classic’ digitization of analog envelope signal.

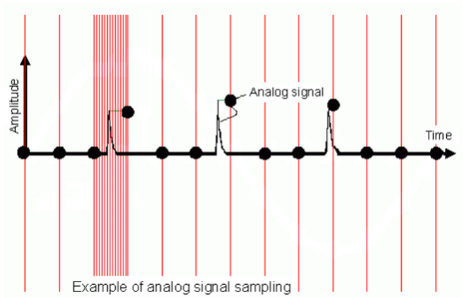

High-speed sampling techniques, originally available in Emerson’s PeakVue technique and more recently in monitoring systems from several manufacturers like I-care’s I-DNA, SPM HD or SKF tremendously improved the tools accessible to the analyst. Sampling frequencies up to and beyond 100kHz expand the monitored frequency range up to 40kHz, allowing to detection of the high frequencies generated by friction resulting from improper lubrication or associated with the stress waves generated by low-speed bearing defects. This technique is illustrated in Figure 2, showing the detection of very short impacts using high-frequency sampling, while still keeping the same amount of samples in the digitized waveform as with conventional (envelope) techniques.

Figure 2. Digitization of analog signal using high-frequency sampling

So, in the question of whether vibration analysis is as powerful as ultrasound in the detection of lubrication issues and low-speed bearing defect monitoring, the answer is clearly yes, if vibration analysis includes one of the high-frequency sampling techniques. To answer the second question, if ultrasound and vibration analysis can still be complementary techniques, the answer is also positive. Ultrasound will not detect failure modes in rotating equipment that cannot be detected with high-frequency vibration analysis techniques. So, from a technological point of view, it will not provide the rotating equipment analyst with information he couldn’t obtain with vibration. Ultrasound can however still be a fast and efficient way to serve as a quick screening method for bearing and lubrication conditions, and in that way be a valuable addition to a condition monitoring program. Still have questions or want to learn more about vibration analysis and ultrasound techniques, contact us today and speak to Kris Deckers or one of our many predictive maintenance experts. I-care, changing the way the world performs.